Tiny “black holes” on a silicon wafer make for a new type of photodetector that could move more data at lower cost around the world or across a data center. The technology, developed by electrical engineers at the University of California, Davis, and W&WSens Devices Inc. of Los Altos, California, a Silicon Valley startup, is described in a paper published April 3 in the journal Nature Photonics.

“We’re trying to take advantage of silicon for something silicon cannot usually do,” said Saif Islam, professor of electrical and computer engineering at UC Davis, who co-led the project together with the collaborators at W&WSens Devices Inc. Existing high-speed photodetector devices use materials such as gallium arsenide. “If we don’t need to add nonsilicon components and can monolithically integrate with electronics into a single silicon chip, the receivers become much cheaper.”

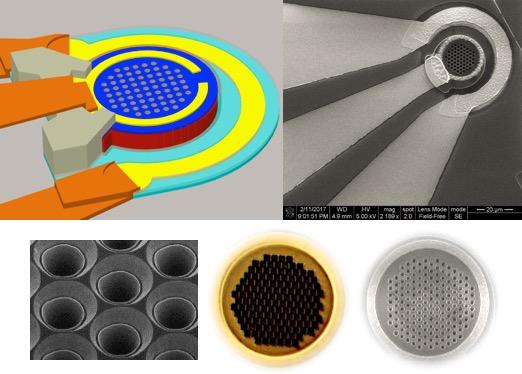

The new detector uses tapered holes in a silicon wafer to divert photons sideways, preserving the speed of thin-layer silicon and the efficiency of a thicker layer. So far, Islam’s group has built an experimental photodetector and solar cell using the new technology. The photodetector can convert data from optical to electronics at 20 gigabytes per second (or 25 billion bits per second, more than 200 times faster than your cable modem) with a quantum efficiency of 50 percent, the fastest yet reported for a device of this efficiency.

Data centers need fast connections

The growth of data centers that power the internet “cloud” has created a demand for devices to move large amounts of data, very fast, over short distances of a few yards to hundreds of yards. Such connections could also be used for high-speed home connections, Islam said.

When computer engineers want to move large amounts of data very fast, whether across the world or across a data center, they use fiber-optic cables that transmit data as pulses of light. But these signals need to be converted to electronic pulses at the receiving end by a photodetector. You can use silicon as a photodetector — incoming photons generate a flow of electrons. But there’s a tradeoff between speed and efficiency. To capture most of the photons, the piece of silicon needs to be thick, and that makes it relatively slow. Make the silicon thinner so it works faster, and too many photons get lost.

Instead, circuit designers have used materials such as gallium arsenide and indium phosphide to make high-speed, high-efficiency photodetectors. Gallium arsenide, for example, is about 10 times as efficient as a silicon at the same scale and wavelength. But it is significantly more expensive and cannot be monolithically integrated with silicon electronics.

Tapered holes as light traps

Islam’s group began by experimenting with ways to increase the efficiency of silicon by adding tiny pillars or columns, then holes to the silicon wafer. After two years of experiments, they settled on a pattern of holes that taper toward the bottom.

“We came up with a technology that bends the incoming light laterally through thin silicon,” Islam said.

The idea is that photons enter the holes and get pulled sideways into the silicon. The wafer itself is about 2 microns thick, but because they move sideways, the photons travel through 30 to 40 microns of silicon, like the ripple of waves on a pond when a pebble is dropped into the water.

The holes-based device can also potentially work with a wider range of wavelengths of light than current technology, Islam said.

Additional authors on the paper are: at UC Davis, Yang Gao, Hilal Cansizoglu, Kazim Polat, Soroush Ghandiparsi, Ahmet Kaya, Hasina Mamtaz, Ahmed Mayet, Yinan Wang, Xinzhi Zhang and Aly Elrefaie; Toshishige Yamada at UC Santa Cruz and W&WSens Devices Inc.; Ekaterina Ponizovskaya Devine and Shih-Yuan Wang, W&WSens Devices Inc.

The work was supported by the S.P. Wang and S.Y. Wang Partnership, the U.S. National Science Foundation and the Army Research Office.