In a fusion of old-world craft and modern engineering, Columbia University researchers have accomplished something remarkable: they’ve used traditional knitting techniques to create sophisticated radio-frequency antennas that could revolutionize how we communicate in remote locations. These lightweight, foldable devices perform like satellite dishes but can be worn like sweaters or carried like blankets, opening new possibilities for communications in challenging environments.

Published in Advanced Materials | Estimated reading time: 7 minutes

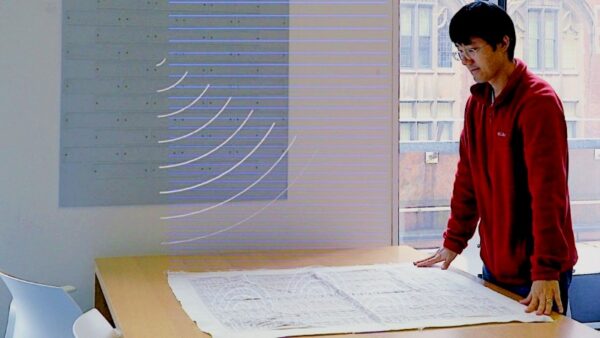

The intersection of ancient craft and cutting-edge technology rarely produces practical solutions for modern problems. Yet in the laboratories of Columbia Engineering, a team led by Dr. Nanfang Yu, associate professor of applied physics and applied mathematics, has achieved exactly that. Using the same knitting technique found in traditional Fair Isle sweaters, they’ve created sophisticated radio-frequency antennas that could transform how we communicate across vast distances.

Radio-frequency antennas are fundamental to modern communications, from satellite television to mobile networks. Traditional RF antennas, particularly the highly directional array antennas known as reflectarrays, are typically rigid, bulky devices that, while effective, pose significant challenges for transportation and deployment. These limitations become particularly acute in remote locations or space applications, where every gram of weight and cubic centimeter of space counts.

The breakthrough lies in the team’s innovative use of float-jacquard knitting, a centuries-old technique traditionally used to create intricate patterns in wool sweaters. In this method, different types of yarn are selectively shown or “floated” beneath the fabric to create patterns. The Columbia team adapted this technique to work with metallic and dielectric yarns, effectively weaving sophisticated antenna arrays directly into fabric during the manufacturing process.

Previous attempts to create flexible antennas have relied on methods like inkjet printing or screen-printing conductive materials onto existing textiles. These approaches often led to problems such as delamination, where the conductive material separates from the fabric, or cracking of the metallic regions. By integrating the antenna pattern during the actual fabric creation process, Yu’s team has eliminated these structural weaknesses while simultaneously solving the challenge of mass production.

The efficiency of this approach is remarkable. Each prototype metasurface, covering approximately one square meter, takes just 45 minutes to produce. The resulting devices demonstrated impressive capabilities: when operating as receiving antennas, they can focus incoming centimeter-waves into precise focal points, and as transmitting antennas, they can transform divergent waves into highly directional beams. Perhaps most importantly, these textile antennas proved durable enough to withstand repeated washing and stretching.

The team went beyond basic antenna functionality to demonstrate more advanced applications. They created a vortex-beam generating metasurface that produces beams with corkscrew-shaped wavefronts. This innovation allows for an independent channel of information, effectively doubling the efficiency of communication channels when used alongside conventional beams.

The scalability of this technology is particularly promising. Commercial flat-knitting machines can produce textiles up to two meters in width with no length limitations. This capability could enable the creation of high-gain antennas with apertures several meters in diameter that remain lightweight and stowable enough for satellite deployment, potentially transforming space-based communications.

Dr. Yu’s team achieved these results using commercially available yarns and existing manufacturing techniques, suggesting that widespread adoption could be relatively straightforward. The technology holds promise not just for specialized applications but could eventually lead to consumer products like WiFi-boosting garments that combine functionality with everyday wear.

Key Terms

- Float-Jacquard Knitting

- A traditional knitting technique where different types of yarn are selectively shown on the surface or “floated” beneath the fabric to create patterns, adapted here to create functional antenna arrays.

- Metasurface

- An ultra-thin optical component that can control and manipulate the propagation of electromagnetic waves, including radio frequencies.

- Vortex Beam

- An electromagnetic beam with a corkscrew-shaped wavefront that can carry independent channels of information, increasing communication efficiency.

Test Your Knowledge

How long does it take to knit one square meter of the antenna material?

Each prototype metasurface with a footprint of approximately one square meter was knit within 45 minutes.

What advantage does float-jacquard knitting have over previous flexible antenna approaches?

Unlike methods like inkjet or screen printing that add conductive materials to existing textiles, float-jacquard knitting integrates the antenna pattern during fabric creation, avoiding problems like delamination and cracking.

How does the vortex-beam generating metasurface improve communication efficiency?

The vortex beam’s corkscrew-shaped wavefront can carry an independent channel of information, allowing it to work alongside conventional beams to double the efficiency of a communications channel.

What technical limitations of commercial flat-knitting could affect the scaling of this technology for space applications?

Commercial flat-knitting machines can produce textiles up to two meters in width with no length limitations, making them suitable for creating large high-gain antennas for satellite communications, though width remains constrained by the two-meter maximum.

Enjoy this story? Subscribe to our newsletter at scienceblog.substack.com.