Scientists are developing sophisticated sensors to see and hear inside the world’s most difficult places, such as turbine engines, boilers, gasifiers and fuel cells.

In these extremely harsh environments information relay is critical, but getting accurate information can be tough — it’s hard to hear inside a roaring turbine or see inside a blazing furnace. At the National Energy Technology Laboratory (NETL), researchers are developing advanced sensors that will enable next-generation energy systems to operate at optimal efficiency, saving massive amounts of energy and CO2 in the process.

Energy research requires special tools. NETL scientist Dr. Michael Buric explains that energy environments are much more intense than the temperature, pressure, light and sound levels we experience in our everyday lives. “In fact, huge power plants and energy facilities have the harshest, most difficult environments anywhere on the planet.”

Sensors are needed because it is physically impossible for energy researchers to climb into a boiler or dissect an operating fuel cell. But in a complex system with thousands of moving parts, affixing extra wires or cables can disrupt finely tuned equipment and lead to inaccurate readings.

That’s where lasers come in.

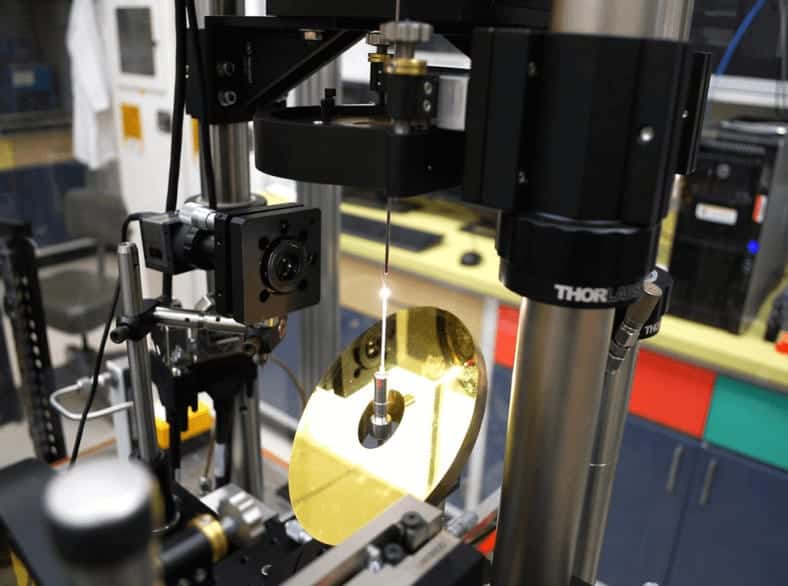

Rather than using wires to transmit data, sensors can be designed to use lasers that don’t get in the way. Better sensors using lasers could detect leaks or corrosion along hundreds of kilometers of gas pipelines spanning the country. They could monitor and control high-temperature fuel cells that convert hydrogen to electricity with virtually no emissions. They could even measure the conditions inside industrial-scale gasifiers that convert coal or other fuels directly into electricity to improve efficiency, use less fuel and emit fewer greenhouse gases.

NETL researchers use a wide variety of different types of lasers, as well as waveguides, fiber-optics and new materials engineered to survive the hottest, toughest environments possible. This requires a team with many different areas of expertise, including mechanical engineers, materials scientists and optics experts. The results of these collaborations are sensors that provide new measurements and pioneering monitoring strategies to make our energy production technologies more efficient so we can generate more power with fewer resources and less emissions.

The world of sensors may seem like a small cog in the wheel of complex power systems, but the research stands to offer major benefits. Much of the work is focused on cleaning up fossil fuel technologies, which still provide most of the world’s power. Dr. Buric is optimistic about the future: “If our team succeeds at improving operations even a small amount, the world can reap huge benefits as those technologies make their way into power systems around the world.”