A Northwestern University research team has developed a versatile composite fabric that can deactivate both biological threats, such as the novel coronavirus that causes COVID-19, and chemical threats, such as those used in chemical warfare. A material that is effective against both classes of threats is rare.

The material also is reusable. It can be restored to its original state after the fabric has been exposed to threats by a simple bleach treatment. The promising fabric could be used in face masks and other protective clothing.

“Having a bifunctional material that has the ability to deactivate both chemical and biological toxic agents is crucial since the complexity to integrate multiple materials to do the job is high,” said Northwestern’s Omar Farha, an expert in metal-organic frameworks, or MOFs, which is the basis for the technology.

Farha, a professor of chemistry in the Weinberg College of Arts and Sciences, is a co-corresponding author of the study. He is a member of Northwestern’s International Institute for Nanotechnology.

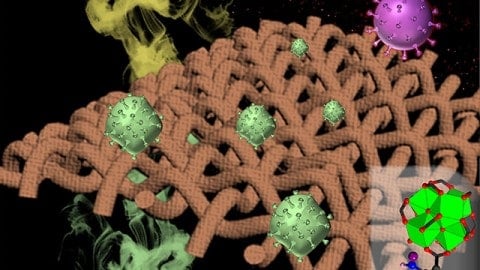

The MOF/fiber composite builds on an earlier study in which Farha’s team created a nanomaterial that deactivates toxic nerve agents. With some small manipulations, the researchers were able to also incorporate antiviral and antibacterial agents into the material.

MOFs are “sophisticated bath sponges,” Farha said. The nano-sized materials are designed with a lot of holes that can capture gases, vapors and other agents the way a sponge captures water. In the new composite fabric, the cavities of the MOFs have catalysts that can deactivate toxic chemicals, viruses and bacteria. The porous nanomaterial can be easily coated on textile fibers.

The study was published recently in the Journal of the American Chemical Society (JACS).

The researchers found that the MOF/fiber composite exhibited rapid activity against SARS-CoV-2 and both gram-negative bacteria (E. coli) and gram-positive bacteria (S. aureus). Also, the active chlorine-loaded MOF/fiber composite rapidly degraded sulfur mustard gas and its chemical simulant (2-chloroethyl ethyl sulfide, CEES). The nanopores of the MOF material coated on the textile are wide enough to allow sweat and water to escape.

The composite material is scalable, Farha added, as it only requires basic textile processing equipment currently used by industry. When incorporated into a facemask, the material should be able to work both ways: protecting the mask wearer from virus in his or her vicinity as well as protecting individuals who come into contact with an infected person wearing the mask.

The researchers also were able to develop an understanding of the material’s active sites down to atomic level. This allows them and others to derive structure-property relationships that can lead to the creation of other MOF-based composites.

The research was supported by a National Science Foundation RAPID grant (2029270), the Army Research Office (W911NF2020136) and the Defense Threat Reduction Agency (HDTRA1-18-1-0003 and CB3934).

The title of the paper is “Immobilized Regenerable Active Chlorine within a Zirconium-Based MOF Textile Composite to Eliminate Biological and Chemical Threats.” Yuk Ha Cheung of The Hong Kong Polytechnic University and Kaikai Ma of Northwestern University are first authors of the paper. Ma also is a co-corresponding author.

EDITOR’S NOTE: Omar Farha has a financial interest in the startup company NuMat Technologies, which is seeking to commercialize metal-organic frameworks.