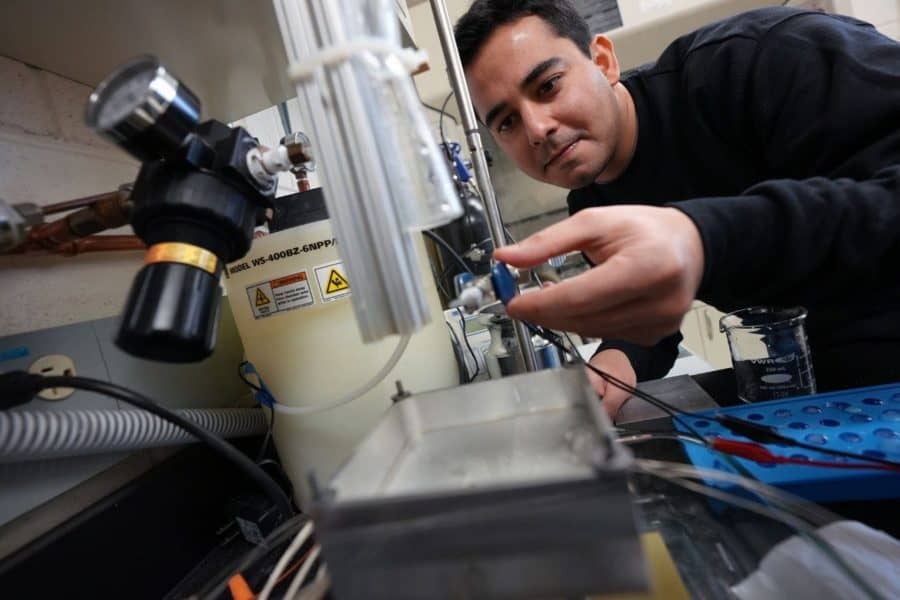

Associate Professor Jonathan Boreyko and graduate fellow Mojtaba Edalatpour have made a discovery about the properties of water that could provide an exciting addendum to a phenomenon established over two centuries ago. The discovery also holds interesting possibilities for cooling devices and processes in industrial applications using only the basic properties of water. Their work was published on Jan. 21 in the journal Physical Review Fluids.

Water can exist in three phases: a frozen solid, a liquid, and a gas. When heat is applied to a frozen solid, it becomes a liquid. When applied to the liquid, it becomes vapor. This elementary principle is familiar to anyone who has observed a glass of iced tea on a hot day, or boiled a pot of water to make spaghetti.

When the heat source is hot enough, the water’s behavior changes dramatically. According to Boreyko, a water droplet deposited onto an aluminum plate heated to 150 degrees Celsius (302 degrees Fahrenheit) or above will no longer boil. Instead, the vapor that forms when the droplet approaches the surface will become trapped beneath the droplet, creating a cushion that prevents the liquid from making direct contact with the surface. The trapped vapor causes the liquid to levitate, sliding around the heated surface like an air hockey puck. This phenomenon is known as the Leidenfrost effect, named for the German doctor and theologian who first described it in a 1751 publication.

This commonly accepted scientific principle applies to water as a liquid, floating on a bed of vapor. Boreyko’s team found themselves wondering: Could ice perform in the same way?

“There are so many papers out there about levitating liquid, we wanted to ask the question about levitating ice,” said Boreyko. “It started as a curiosity project. What drove our research was the question of whether or not it was possible to have a three-phase Leidenfrost effect with solid, liquid, and vapor.”

Going into the ice

Curiosity sparked the first investigation in Boreyko’s lab some five years ago in the form of a research project by then-undergraduate student Daniel Cusumano. What he observed was fascinating. Even when the aluminum was heated above 150 C, the ice did not levitate on vapor as liquid does. Cusumano continued raising the temperature, observing the behavior of the ice as the heat increased. What he found was that the threshold for levitation was dramatically higher: 550 C (1022 F) rather than 150 C. Up until that threshold, the meltwater beneath the ice continued to boil in direct contact with the surface, rather than exhibit the Leidenfrost effect.

What was going on underneath the ice that prolonged the boiling? The project was picked back up by graduate student Mojtaba Edalatpour a short time later, to solve the mystery. Edalatpour had been working with Boreyko to develop novel methods of heat transfer and put that knowledge to work in approaching this problem. The answer turned out to be the temperature differential in the meltwater layer beneath the ice. The meltwater layer has two different extremes: Its bottom is boiling, which fixes the temperature at about 100 C, but its top is adhered to the remaining ice, which fixes it at about 0 C. Edalatpour’s model revealed that the maintenance of this extreme temperature differential consumes most of the surface’s heat, explaining why levitation was more difficult for ice.

Boreyko elaborated. “The temperature differential the ice is uniquely creating across the water layer has changed what happens in the water itself, because now most of the heat from the hot plate has to go across the water to maintain that extreme differential. So only a tiny fraction of the energy can be used to produce vapor anymore.”

The elevated temperature of 550 degrees Celsius for the icy Leidenfrost effect is practically important. Boiling water is optimally transporting heat away from the substrate, which is why you feel ample heat rising from a pot of water that is boiling but not from a pot of water that is merely hot. This means that the difficulty in levitating ice is actually a good thing, as the larger temperature window for boiling will result in better heat transfer compared to using a liquid alone.

“It is much harder to levitate the ice than it was to levitate the water droplet,” said Boreyko. “Heat transfer plummets as soon as levitation begins, because when liquid levitates, it doesn’t boil anymore. It’s floating over the surface rather than touching, and touching is what causes it to boil the heat away. So, for heat transfer, levitation is terrible. Boiling is incredible.”

Using ice for heat transfer

As the team explored possibilities for practical application, they looked to their existing work. Since Edalatpour had extensive research in heat transfer, that topic became a logical fit.

Heat transfer comes most into play for cooling off things like computer servers or car engines. It requires a substance or mechanism that can move energy away from a hot surface, redistributing heat quickly to reduce the wear and tear on metal parts. In nuclear power plants, the application of ice to induce rapid cooling could become an easily-deployed emergency measure if power fails, or a regular practice for servicing power plant parts.

There are also potential applications for metallurgy. To produce alloys, it is necessary to quench the heat from metals that have been shaped in a narrow window of time, making the metal stronger and less brittle. If ice were applied, it would allow heat to be offloaded rapidly through the three water phases, quickly cooling the metal.

Boreyko also foresees a potential for applications in firefighting.

“You could imagine having a specially made hose that is spraying ice chips as opposed to a jet of water,” he said. “This is not science fiction. I visited an aerospace company that has an icing tunnel and they already have this technology where a nozzle sprays out ice particles as opposed to water droplets.”

With myriad possibilities, Boreyko and Edalatpour are excited about the new contribution that has come to the science world. Looking back over the past five years, they still credit this exciting development to their shared spark of curiosity and the drive to be creative in research.