Researchers from the Singapore-MIT Alliance for Research and Technology (SMART), MIT’s research enterprise in Singapore, have identified a critical quality attribute (CQA) that potentially allows the development of a rapid and sensitive process analytical technology for sterility. Specifically, this technology enables the detection of early-stage microbial contamination in human cell therapy products (CTPs).

Cell therapy represents one of the most advanced biotechnology revolutions in medicine, with strong potential to repair damaged tissues and treat a range of conditions such as degenerative diseases and cancer. It works by delivering living cells to replace or repair damaged tissue and cells. Notably, the manufacturing processes of many CTPs are complex, and the products themselves have short shelf lives. During the manufacturing process, cells in culture are vulnerable to microbial contamination due to the use of nutrient media, which supports human cell growth but can also support the growth of harmful microorganisms. Therefore, CTPs present a risk of possible transmission of infectious agents from cells to patients, which may cause serious bacterial infections.

To control microbial risks and ensure the product safety of CTPs, sterility testing and monitoring are required in the manufacturing process and before patient infusion. This can be achieved by identifying CQAs, which are key properties or characteristics of CTPs that should fall within appropriate limits or ranges to achieve the products’ desired quality. The identification of a secreted metabolite biomarker thus paves the way toward developing a rapid and accurate sterility test method that could determine microbial safety as early as possible, without also affecting the human cells that serve as the patient’s medicine.

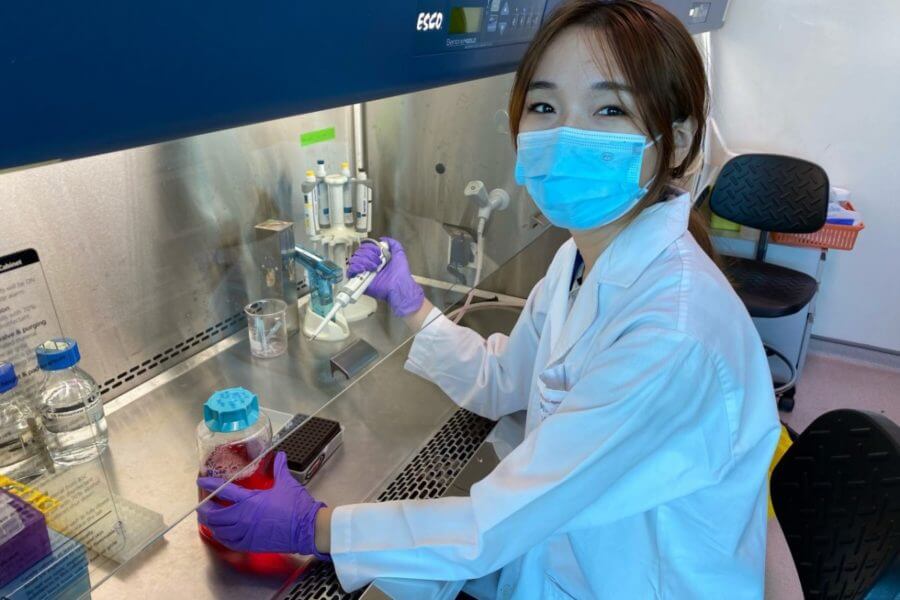

A breakthrough developed by researchers in SMART’s Critical Analytics for Manufacturing Personalized-Medicine (CAMP) interdisciplinary research group, is critical in overcoming the challenges of widespread adoption and manufacturing of CTPs.

The method developed by CAMP utilizes the ratio of two metabolites, nicotinic acid to nicotinamide, as a biomarker to detect a broad spectrum of microbial contaminants in cell cultures. The team’s research is explained in a paper titled “The ratio of nicotinic acid to nicotinamide as a microbial biomarker for assessing cell therapy product sterility,” published recently in the journal Molecular Therapy: Methods & Clinical Development.

“This team-based, interdisciplinary approach to technology development that addresses critical bottlenecks in cell therapy manufacturing — including safety assessment that is as fast as therapy production — is a hallmark of SMART CAMP’s research goals,” says Krystyn Van Vliet, MIT professor of materials science and engineering, associate provost, and associate vice president for research who is also co-lead of SMART CAMP with Hanry Yu, professor at the National University of Singapore.

As part of the research, the media (or fluid) of cell therapy products that were intentionally contaminated or uncontaminated with microbes were collected and analyzed through liquid chromatography-mass spectrometry-based metabolomics. The researchers identified secreted metabolites that were uniquely found in microbe-contaminated human cell cultures but not in uncontaminated ones, based on the analysis.

Among these metabolites found in human cell culture media, nicotinic acid was found to be widely conserved in cell cultures contaminated with multiple types of microorganisms. Upon further analysis, CAMP’s studies revealed that nicotinic acid production was associated with nicotinamidase, an enzyme that converted the nicotinamide in the culture medium into nicotinic acid. The research findings showed that nicotinamidase was not found in mammals, including humans, and the majority was found in bacteria species. Therefore, the ratio of nicotinic acid to nicotinamide indicated the presence of microbial contaminations in human CTPs.

This method surpasses existing and conventional techniques in terms of both sensitivity and speed. It can detect microbial contaminations in half-a-day, depending on the type of microorganism tested. In contrast, conventional methods require up to 14 days for detection. Alternative microbiological methods also face several limitations, such as the invasive process of cell extraction from and during the manufacturing process, requiring an incubation period for microbial enrichment that lengthens detection time to multiple days, or detecting only a limited range of bacterial species.

Overcoming existing limitations, the method developed by CAMP is able to detect cell therapy contamination rapidly, using a small volume of spent cell culture medium in a non-cell destructive manner while maintaining the human CTP. Furthermore, this approach can differentiate between live and dead bacteria. Dead bacteria are non-infectious, and the ability to identify and measure only live bacteria, which pose a health threat, could lead to lower false-positive rates.

“Our novel analytical test method is the first reported method that identified a secreted metabolite biomarker as a potential sterility CQA to detect microbial contaminations caused by a broad range of microbial species. The method addresses one of the key challenges of developing a rapid sterility process analytical technology in the manufacturing process of CTPs to ensure the timely and accurate assessment of microbial safety, which will accelerate the adoption and production of high-quality CTPs,” says Jiayi Huang, senior postdoc at SMART CAMP and lead author of the paper.

“This sterility biomarker has the possibility to become a rapid method for early detection of microbes for manufacturers. As we can sample the supernatant of the cell therapy product directly without the need for subculturing precious cells, this could be an important advantage for monitoring along the cell therapy production process. We are pursuing a number of translational paths forward, including small-scale mass spectrometry and optical methods,” adds Stacy L. Springs, principal investigator at SMART CAMP, executive director at the MIT Center for Biomedical Innovation, and co-corresponding author.

This discovery also benefited from the perspectives of co-authors Scott Rice, principal investigator at SMART CAMP, faculty at National Technical University, and deputy research director at Singapore Center for Environmental Life Sciences Engineering with expertise in microbial communities; and Yie Hou Lee, scientific director of SMART CAMP with expertise in metabolomic analysis.

The study provides a new way to detect adventitious microbial contamination based on the microbes’ secreted metabolite into the human cell culture’s surrounding fluid or supernatant. The team at SMART CAMP is currently working on translating the research to an innovative sterility process analytical technology to improve CTP quality. The impact of the research findings also applies beyond the field of medicine, offering new possibilities for the development of relevant products and technologies to detect microbial contamination in other industries, including health care, food, cosmetics, and the environment.

The research is carried out by SMART and supported by the National Research Foundation (NRF) Singapore under its Campus for Research Excellence And Technological Enterprise (CREATE) program.

CAMP is a SMART interdisciplinary research group launched in June 2019. It focuses on better ways to produce living cells as medicine, or cellular therapies, to provide more patients access to promising and approved therapies. The investigators at CAMP address two key bottlenecks facing the production of a range of potential cell therapies: CQA and PAT. Leveraging deep collaborations within Singapore and MIT in the United States, CAMP invents and demonstrates CQA/PAT capabilities from stem to immune cells. Its work addresses ailments ranging from cancer to tissue degeneration, targeting adherent and suspended cells, with and without genetic engineering.

CAMP is the R&D core of a comprehensive national effort on cell therapy manufacturing in Singapore.

SMART was established by MIT and the NRF in 2007. SMART is the first entity in CREATE. SMART serves as an intellectual and innovation hub for research interactions between MIT and Singapore, undertaking cutting-edge research projects in areas of interest to both. SMART currently comprises an Innovation Center and five IRGs: Antimicrobial Resistance, CAMP, Disruptive and Sustainable Technologies for Agricultural Precision, Future Urban Mobility, and Low Energy Electronic Systems.