Harvesting energy sources such as heat, vibration, light, and electromagnetic waves from everyday environments such as industrial sites and automobiles and converting them into electrical energy is known as energy harvesting. Energy harvesting makes it easier to power today’s popular IoT sensors and wireless devices that are located in environments where battery replacement is difficult.

Dr. Hyun-Cheol Song and Dr. Sunghoon Hur of Electronic Materials Research Center at the Korea Institute of Science and Technology (KIST) have developed a hybrid energy harvesting system that increases power production by more than 50% by combining thermoelectric and piezoelectric effects.

The thermoelectric effect, which converts thermal energy from both ends of the device into electrical energy, has a low energy conversion efficiency, and the piezoelectric effect, which converts mechanical vibration into electrical energy, has a high impedance, so energy cannot be reliably harvested. To overcome the limitations of single-mode energy harvesters, hybrid energy harvesters have been proposed in the past, but they are mainly based on simply combining the energy generated by each mechanism.

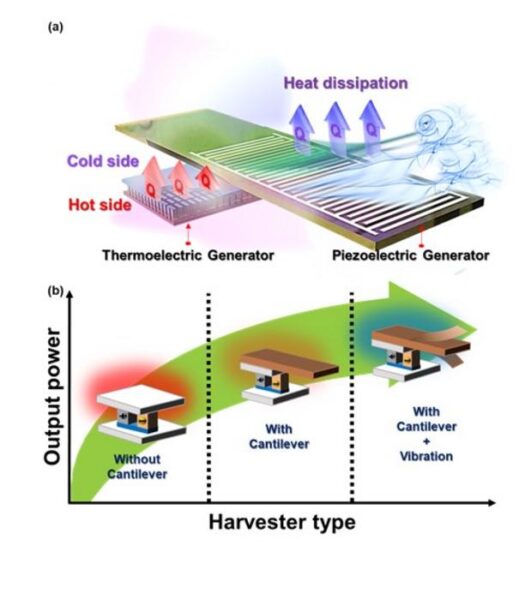

In response, the KIST research team developed a thermoelectric-piezoelectric hybrid energy harvester that complements the shortcomings of thermoelectric and piezoelectric devices to create a synergistic effect in environments with heat sources and vibrations. First, instead of a heat sink, which is a static shape with a large cross-sectional area that is bulky and in contact with air, a cantilever was fabricated to improve the heat dissipation effect in a vibration environment, resulting in a thermoelectric device output that was improved by more than 25%. The researchers also proposed a hybrid energy harvesting structure in which a polymer-type piezoelectric device (MFC) was attached to the cantilever to generate additional power by generating tensile and compressive deformation of the piezoelectric device as the cantilever shakes. The research team successfully applied this hybrid energy harvester to stably drive a commercial IoT sensor (GPS positioning sensor, 3 V, 20 mW), demonstrating the potential for future IoT sensors to run continuously without battery power supply.

“This study confirms that the hybrid energy harvesting system can be reliably applied to our real life,” said Dr. Sunghoon Hur of KIST, who led the research. “We have confirmed its effectiveness in places where heat and vibration exist together, such as automobile engines, and are currently planning to build a system that can be applied to factory facilities or construction machinery engines that are difficult to supply power and diagnose their condition wirelessly.”