There’s a lot of research about moving away from carbon as an energy source, but what if instead the carbon that is being used is applied to its full capacity?

The importance of carbon as an energy source is not to be downplayed. Unfortunately, the reliance on these carbon-based materials has proven to be disastrous for the environment, especially in the quantities they are consumed on a global basis. Therefore, alternative means have to be researched. Superstructure carbons (SCC) are a possible way to use carbons in a more efficient and “green” way that can exceed the current performance and longevity of the standard materials in energy storage and conversion devices.

Researchers published the findings in Energy Materials and Devices on January 30.

SCCs are multifaceted in both their construction and performance but also in their concept as a whole. It starts with the fact that they are, indeed, carbons. While this might not seem like a step to reduce overall carbon dependency, it is a way to make the carbons being used more intentionally with more direct functions that can lead to better performance and functionality

“This unique category satisfies the particular functional demands of high-performance devices and surpasses the rigid structure of traditional carbons,” said Debin Kong, researcher and author of the study.

SSCs are carbon-based materials that are built precisely for the material it’s interfacing with, whether that’s a lithium-ion (Li) battery, lithium sulfide (LiS) battery or a metal-air battery.

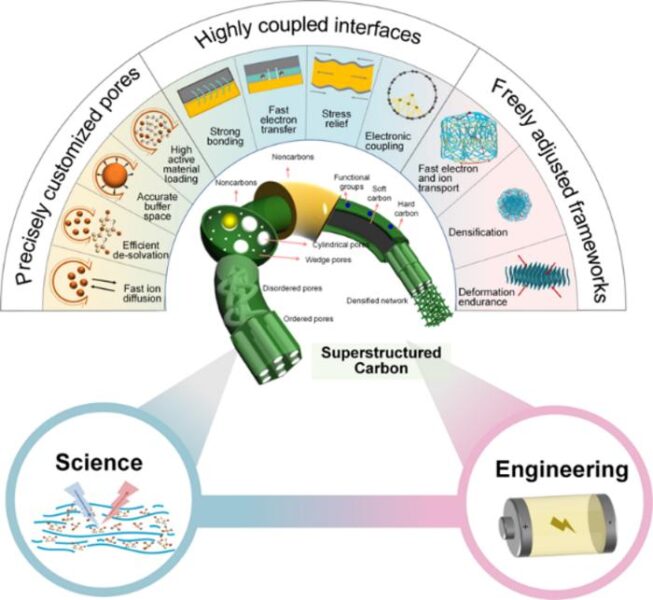

There are three main characteristics of these SCCs presented by researchers for successful development and implementation: precisely customized pores, freely adjusted frameworks and highly coupled interfaces.

Having precisely customized pores has the advantage of improved surface utilization and mass transfer over traditional carbon materials. Using a porous carbon as part of the active material in energy-storage devices (like batteries) can improve metrics such as the specific capacity of the material. The specific capacity is the amount of an electrical charge that can be delivered to the material per gram of the material’s weight. Freely adjusted frameworks are crucial to allow for rapid electron transfer between the inner workings of the materials, including the carbon unit and electrode. Finally, highly coupled interfaces allow for an additional improvement in electron transfer, which is a significant element in improving the overall function and performance of a battery. Interfaces that work well together allow for electrochemical reactions to occur more easily and without issues such as aggregation, or the formation of clusters of nanoparticles.

“Overall, the concept of SSCs shows a way to solve the problems faced by current carbons, which is important to the practical applications of advanced carbons and their relevant high performance energy related devices in future,” said Kong.

Researchers aren’t aiming to just improve carbon-based active materials with this review, but are looking to create new highs for carbon structures. Performance breakthroughs are an ultimate goal, aiming to shatter bottlenecks in the performance of energy conversion and storage. However, there are always difficulties to consider and wrinkles to iron out with further research.

The most important thing to consider is that different devices have different needs. Li, LiS and metal-air batteries are likely to all have a different relationship with SCCs that needs to be fully fleshed out to ensure suitability and compatibility. Additionally, the cost and performance of SCCs need to be examined before it becomes a practical and widespread solution. This can include refining the preparation process and the precursors needed to lower the cost and simplify production. Another point that needs further research is the overall understanding of the carbon microstructure and its structural evolution depending on the carbon precursor used.

Debin Kong, Wei Lv, Yanbing He, and Feiyu Kang of the Shenzhen Giem Graphene Center and Engineering Laboratory for Functionalized Carbon Materials at Tsinghua University with Debin Kong also of the College of New Energy at China University of Petroleum, Ruliang Liu, Dingcai Wu, and Ruowen Fu of the Materials Science Institute at Sun Yat-sen University, Feng Li of the Shenyang National Laboratory for Materials Science at the Chinese Academy of Sciences and Quan-Hong Yang of the Nanoyang Group at the School of Chemical Engineering and Technology at Tianjin University all contributed to this research.

The National Basic Research Program of China, the National Nature Science Foundation of China, and the Taishan Scholar Project of Shandong Province made this research possible.