Researchers at Osaka Metropolitan University have made significant strides in understanding the complex interactions between elements in steel, paving the way for the development of superior materials that can enhance the performance and durability of electric vehicle motors.

By optimizing the process of modifying steel surfaces with carbon, nitrogen, and alloy elements, the team aims to create high-performance steel parts that can withstand the rigors of high-speed rotation while reducing vehicle weight.

Exploring 120 Elemental Combinations in Steel

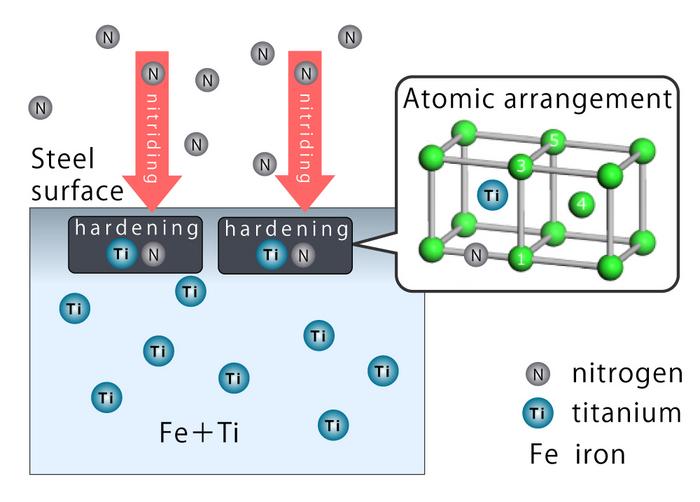

Associate Professor Tokuteru Uesugi and his research group at the Graduate School of Informatics conducted a systematic investigation, theoretically calculating 120 combinations of how 12 alloy elements, such as aluminum and titanium, interact with carbon during carburization and nitrogen in the nitriding process. This comprehensive approach allowed the team to gain valuable insights into the complex interactions between elements in steel.

The results of the study revealed that when titanium is arranged in a specific manner, it forms strong bonds with nitrogen or carbon, effectively hardening the iron. Additionally, the analytical data showed that for an alloy element to bond well, it must have a larger metallic radius than the iron atom.

Unraveling the Mechanism Through Trial and Error

Professor Uesugi acknowledged the challenges faced during the research process, stating, “Although it was not easy to elucidate the mechanism from the results of numerous calculations, we used multiple linear regression and stratified analysis through trial and error.”

Despite the difficulties, the team’s perseverance and innovative approach yielded valuable results that are expected to contribute to a better understanding of the mechanisms behind steel strengthening and improved durability. These findings, published in ISIJ International, will likely play a crucial role in the development of superior materials for electric vehicle motors.

As the world continues to push for the decarbonization of automobiles, the demand for high-performance steel parts that can withstand the unique challenges posed by electric motors continues to grow. The research conducted by Professor Uesugi and his team at Osaka Metropolitan University represents a significant step forward in meeting this demand, bringing us closer to a future of quieter, more durable, and lightweight electric vehicles.

The findings were published in ISIJ International.