Researchers at the University of Tokyo have developed a novel method to transform old concrete into new building materials while simultaneously capturing carbon dioxide. This innovative process could revolutionize the construction industry by creating a circular economy for concrete and reducing its environmental impact.

From Rubble to Resource: The Concrete Recycling Process

The team, led by Professor Ippei Maruyama, has successfully created large, sturdy bricks from demolished concrete and atmospheric CO2. Their method involves several key steps:

1. Grinding old concrete into a fine powder

2. Exposing the powder to CO2 for carbonation

3. Mixing the carbonated powder with a calcium bicarbonate solution

4. Compressing the mixture in layers within a mold

5. Heating the compressed material to form the final brick

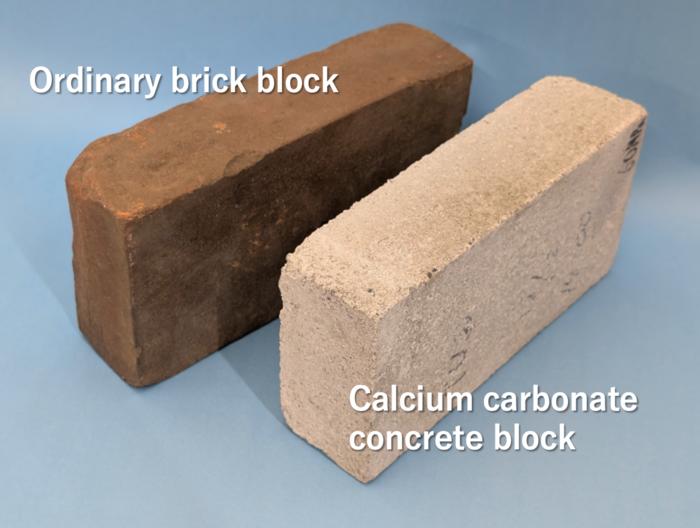

This process builds upon earlier work by the same research group, which had previously produced smaller calcium carbonate concrete samples. The latest advancement allows for the creation of building materials suitable for constructing houses and pavements.

Professor Maruyama explains, “We can make calcium carbonate concrete bricks large and strong enough to build regular houses and pavements. These blocks can theoretically be used semipermanently through repeated crushing and remaking, a process which requires relatively low energy consumption.”

Addressing Sustainability Challenges in Construction

The construction industry faces significant environmental challenges, particularly regarding the production of Portland cement – a key ingredient in traditional concrete. Cement manufacturing is a major contributor to global CO2 emissions, accounting for approximately 8% of the total.

This new recycling method offers several potential benefits:

1. Reducing the need for new limestone extraction, a finite resource

2. Lowering the carbon footprint of construction by reusing materials

3. Capturing and storing CO2 within the new building materials

4. Creating a closed-loop system for concrete use and reuse

The research team tested their process using concrete from a demolished school building, demonstrating that even aged materials can be effectively recycled. By accelerating the natural carbonation process, they were able to create a product with properties similar to conventional concrete.

“Now, concrete in old buildings can be thought of as a kind of urban mine for creating new buildings,” Maruyama notes.

The study, published in the Journal of Advanced Concrete Technology, reports that the new bricks exhibit high density, compressive strength, tensile strength, and Young’s modulus – key indicators of their suitability for construction use.

While the technology is promising, questions remain about its scalability and economic viability. The researchers are addressing these concerns through their ongoing project, C4S (Calcium Carbonate Circulation System for Construction).

“As part of the C4S project, we intend to construct a real two-story house by 2030,” says Maruyama. “Over the next few years, we also plan to move to a pilot plant, where we can improve production efficiency and industrial application, and work on creating much larger building elements, as we move towards making this material commercially available.”

Why it matters: This research represents a significant step towards creating a more sustainable construction industry. By turning urban demolition waste into a valuable resource and sequestering CO2 in the process, this technology could help reduce the environmental impact of building activities. For consumers and policymakers, it offers hope for a future where construction becomes part of the solution to climate change, rather than a contributor to the problem.