Black plastic coffee lids and food containers may finally have a path out of landfills. Scientists have discovered that the very additive that makes these plastics black – carbon black – can help break them down into reusable materials when exposed to sunlight or LED lights. This elegant solution turns a recycling obstacle into part of the solution, offering hope for millions of tons of previously unrecyclable plastic waste.

Published in ACS Central Science | Estimated reading time: 4 minutes

The challenge of recycling black plastics has long frustrated environmental efforts. Most sorting facilities reject these materials because the black pigments interfere with sorting equipment. Now, researchers from Cornell and Princeton Universities have found an unexpected ally in this pigment itself. “Simple, visible light irradiation holds the potential to transform the chemical recycling of plastics, using the additives already found in many commercial products,” explain researchers Sewon Oh, Hanning Jiang, and Erin Stache.

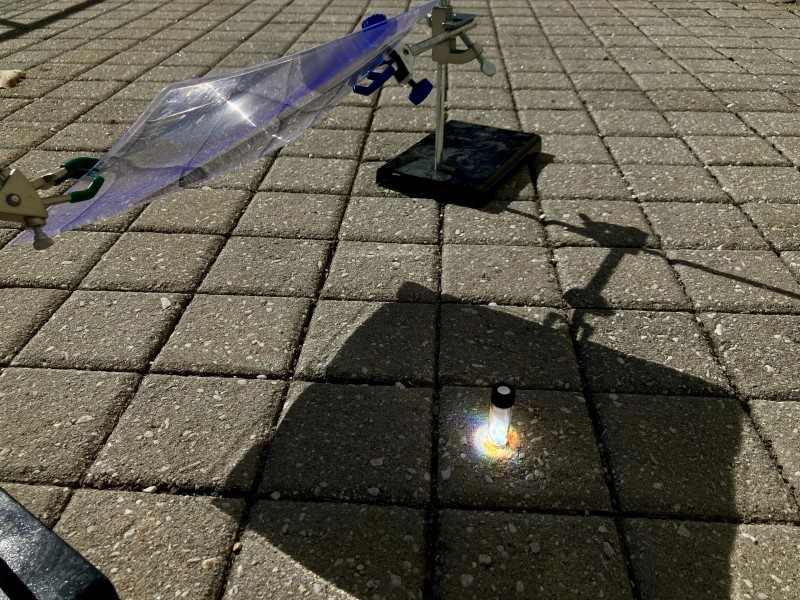

Their method is remarkably straightforward: grind the black plastic into powder, expose it to intense light, and watch as the material breaks down into its building blocks. The carbon black pigment converts light into heat, which then breaks apart the plastic’s molecular structure. When using focused sunlight, the team achieved an impressive 80% conversion rate in just five minutes.

The process works not only on pristine laboratory samples but also on real-world waste. Even plastic contaminated with food residues – think soy sauce and cooking oil – successfully broke down, though at slightly lower rates. Perhaps most promising is the method’s versatility: when researchers mixed black plastic with yellow, red, and clear polystyrene waste, the combination still yielded significant results, with 67% converting under sunlight.

This discovery could reshape our approach to plastic recycling. Instead of viewing black pigments as a barrier, they become catalysts for breakdown, potentially creating a closed-loop system where today’s coffee lid becomes tomorrow’s raw material. The simplicity of using sunlight – our most abundant energy source – makes this technology particularly promising for widespread adoption.

Glossary

- Carbon Black: A pigment additive used to create black plastics, now discovered to help break down plastics when exposed to light

- Polystyrene: A common plastic material used in food containers, coffee lids, and packaging

- Chemical Recycling: A process that breaks down plastics into their original chemical building blocks for reuse

Test Your Knowledge

What makes this recycling method unique compared to traditional approaches?

It uses the black pigment (carbon black) already present in the plastic as a helper to break down the material when exposed to light.

What efficiency rate did the researchers achieve using focused sunlight?

They achieved an 80% conversion rate in just 5 minutes using focused sunlight.

How does this method handle mixed colored plastics?

When mixing black plastic with yellow, red, and clear polystyrene, they achieved a 67% conversion rate under sunlight.

What effect did food contamination have on the recycling process?

Plastics contaminated with substances like canola oil, soy sauce, and orange juice still broke down, though slightly less efficiently than clean samples.

Enjoy this story? Subscribe to our newsletter at scienceblog.substack.com.