Lithium batteries, with their exceptional ability to store power per a given weight, have been a major focus of research to enable use in everything from portable electronics to electric cars. Now researchers at MIT and Brookhaven National Laboratory have found a whole new avenue for such research: the use of disordered materials, which had generally been considered unsuitable for batteries.

In a rechargeable lithium-based battery, lithium ions — atoms that have given up an electron, and thus carry a net charge — are pulled out of the battery’s cathode during the charging process, and returned to the cathode as power is drained. But these repeated round-trips can cause the electrode material to shrink and expand, leading to cracks and degrading performance over time.

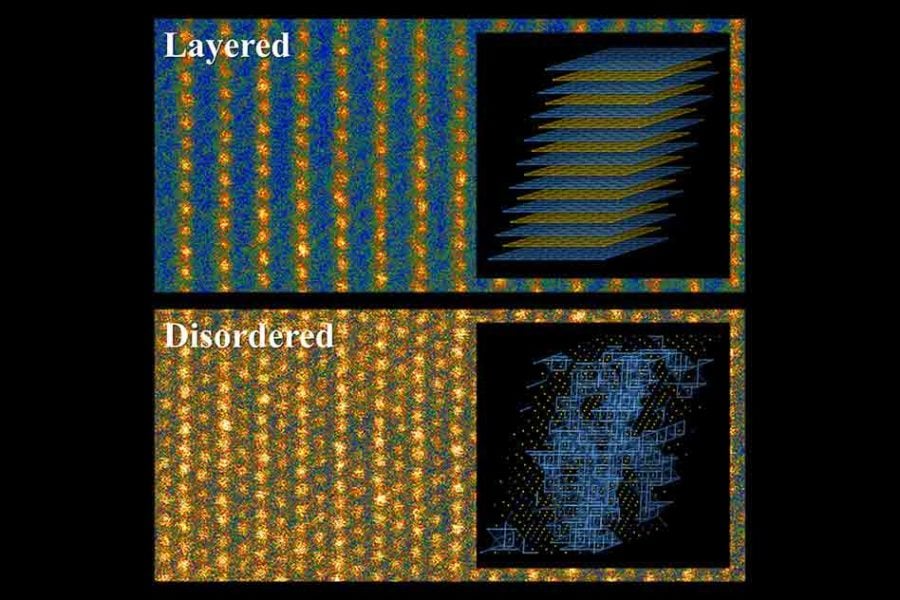

In today’s lithium batteries, those cathodes are usually made of an orderly crystalline material, sometimes in a layered structure. When slight deviations from that perfect order are introduced, the battery’s efficiency generally goes down — so disordered materials have mostly been ignored in the search for improved battery materials.

But it turns out this correlation is far from universal: Certain kinds of disorder can provide a significant boost in cathode performance, the researchers have found through a combination of computer modeling and laboratory experiments. These surprising findings are reported this week in the journal Science, in a paper by MIT graduate student Jinhyuk Lee, professor of materials science and engineering Gerbrand Ceder, and four others.

Ceder describes the materials that can release and then reabsorb the lithium ions as a kind of “reversible sponge.” In today’s batteries, the cathodes are striated materials, made up of lithium layers alternating with oxides of transition metals. Scientists had thought the layering was necessary to provide a pathway for lithium to pass in and out of the cathodes without bumping into the transition metal oxide layer — “a channel with nothing in the way,” as Ceder says.

Moreover, disorder “usually significantly reduces the lithium ion mobility,” Ceder says — and high mobility is essential for an efficient rechargeable battery.

But it turns out that a significant excess of lithium in the material changes things dramatically. In the traditional ordered structure, there is an exact balance between the number of lithium and metal atoms. “But if you get enough of a lithium excess,” Ceder says, “you get new channels, and they can take over from the channels you close off.”

While the disordered material with excess lithium produces irregular pathways, it turns out that these nevertheless can still act as efficient channels for the lithium ions. But such a material offers an extra bonus: While the irregular channels let lithium pass just as easily as it does in a layered material, in the disordered material the lithium ions don’t push the layers out of shape.

The new material — in these experiments, lithium molybdenum chromium oxide — “has a very high dimensional stability,” Ceder says. In most other lithium cathode materials, “as you pull the lithium in and out, it changes dimension, swelling or contracting.” This swelling and contracting “causes all sorts of problems,” including fatigue that can lead to cracking, he says.

While the dimensional changes in layered materials can be as much as 5 to 10 percent, he says, in the new disordered material it is only about 0.1 percent — “virtually zero.”

Ceder stresses that his group’s analysis of this specific compound “shows a new direction that we can take” in searching for even better materials, opening a whole new category of possibilities that had previously been ignored. While lithium molybdenum chromium oxide can hold and release significantly more lithium than existing materials, it produces a lower voltage — meaning its overall performance is about the same as that of existing materials, he says.

Many new materials take decades to move from the laboratory to useful applications, but “we’re hopeful we can do this in one or two years, to discover something better,” Ceder says — most likely by using computational tools such as the Materials Project, which he co-founded.

The research also involved postdocs Alexander Urban, Xin Li, and Geoffroy Hautier at MIT and researcher Dong Su at Brookhaven National Laboratory. It was funded by the Robert Bosch Corporation, Unicore Specialty Optics and Chemicals, Samsung, and the U.S. Department of Energy.

Adapted from a news release issued by MIT