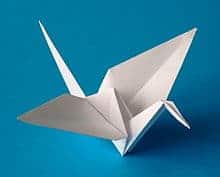

Origami is capable of turning a simple sheet of paper into a pretty paper crane, but the principles behind the paper-folding art can also be applied to making a microfluidic device for a blood test, or for storing a satellite’s solar panel in a rocket’s cargo bay.

A team of Penn researchers is turning kirigami, a related art form that allows the paper to be cut, into a technique that can be applied equally to structures on those vastly divergent length scales.

In a new study, the researchers lay out the rules for folding and cutting a hexagonal lattice into a wide variety of useful three-dimensional shapes. Because these rules ensure the proportions of the hexagons remain intact after the cuts and folds are made, the rules apply to starting materials of any size. This enables materials to be selected based on their relevance to the ultimate application, whether it is in nanotechnology, architecture, or aerospace.

The study was conducted by Toen Castle, a postdoctoral researcher in the Department of Physics & Astronomy in the School of Arts & Sciences; Randall Kamien, a professor in the Department of Physics and Astronomy; and Shu Yang, a professor in the Department of Materials Science and Engineering in the School of Engineering and Applied Science.

A hexagonal lattice may seem like an odd choice for a starting point, but the pattern has advantages over a seemingly simpler tessellation, such as one made from squares.

“The connected centers of the hexagons make triangles,” Castle says, “so, if you start with a hexagonal lattice, you get the triangles for free. It’s like two lattices in one, whereas if you start with squares, you only get squares.”

“Plus,” Yang adds, “it’s easier to fill a space with a hexagonal lattice and move from 2-D to 3-D. That’s why you see it in nature, in things like honeycombs.”

Starting from a flat hexagonal grid on a sheet of paper, the researchers outlined the fundamental cuts and folds that allow the resulting shape to keep the same proportions of the initial lattice, even if some of the material is removed. This is a critical quality for making the transition from paper to materials that might be used in real-world applications.

“The rules we lay out,” Kamien says, “tell you how you make the cuts so you only have to fold on straight lines, and so that, when you fold them together, the rods remain the same length and the centers remain the same distance apart. You may have to bend or put hinges on some of the rods to make the folds, but you don’t have to be able to stretch them.”

“This means it’s just a matter of picking the materials with the properties you want for your application,” Yang says. “We can go from nanoscale materials like graphene to materials you would make clothing out of, to materials you would see in a space station or satellite.”