How can a pleasant vehicle climate be achieved efficiently? Researchers at the Technische Universität München (TUM) pursued this question in the context of the research project Visio.M funded by the German Federal Ministry for Education and Research (BMBF) with a total of 7.1 million euro. The results of their research show that the potential of energy efficient air conditioning is all but exhausted. And this applies also to gasoline powered cars.

Inefficiency has its advantages, too: In the past, waste heat from combustion engines could be used to heat vehicle passenger compartments directly. In warm weather air conditioning provided comfort. But efficient electric motors generate hardly any waste heat. The question of climate control in electric vehicles thus needs to be solved anew.

In the context of the BMBF collaborative project Visio.M, scientists of the TU München researched how to create a subjectively pleasant climate for passengers in the most energy efficient manner. The researchers present the results of their work, implemented in the Visio.M prototype, from 13th to 17th April 2015 in the German government stand (Hall 27, Stand G 64) at the Hannover Messe.

Most previous electric vehicles simply took over concepts from combustion engine vehicles. However, these concept’s thirst for energy put a noticeable dent in vehicle range. The researchers thus took a new look at all potential solutions, considering their efficiency, comfort and cost.

Air conditioning in direct proximity to the passenger

In their research they quickly determined that cooling in direct proximity to the body provided the most efficient alternative. In contrast to previously deployed solutions, in which the entire interior is cooled or heated to the same temperature, heat is generated or dissipated only where it can actually be felt by the passengers.

“Our trials showed that uniform climate control is not necessary,” says Marius Janta, staff member of the Chair for Ergonomics at the TU München. “When we heat the seat of a passenger on cold days, passengers find it pleasant. With only a small amount of energy we can significantly reduce the sense of discomfort.”

The temperature control of the seats in the Visio.M is accomplished using Peltier elements. These are semiconductor elements that can be used for both heating and cooling. “Even though Peltier elements are relatively expensive, they warm up or cool down immediately,” says Alexander Präbst, a staff member at the Chair of Thermodynamics at the TU München. “Compared to the cold start of a combustion engine in winter, they even improve the level of comfort.”

Since Peltier elements are light-weight, they are also deployed in the central air conditioning unit. The installed Peltier elements have a performance capacity of up to 1.6 kW. The elements installed in the seats have a peak performance of 150 W per seat. On very cold days, a supplemental bioethanol heater with a rating of 4.5 kW can be switched on without sacrificing range.

Integrated thermal management

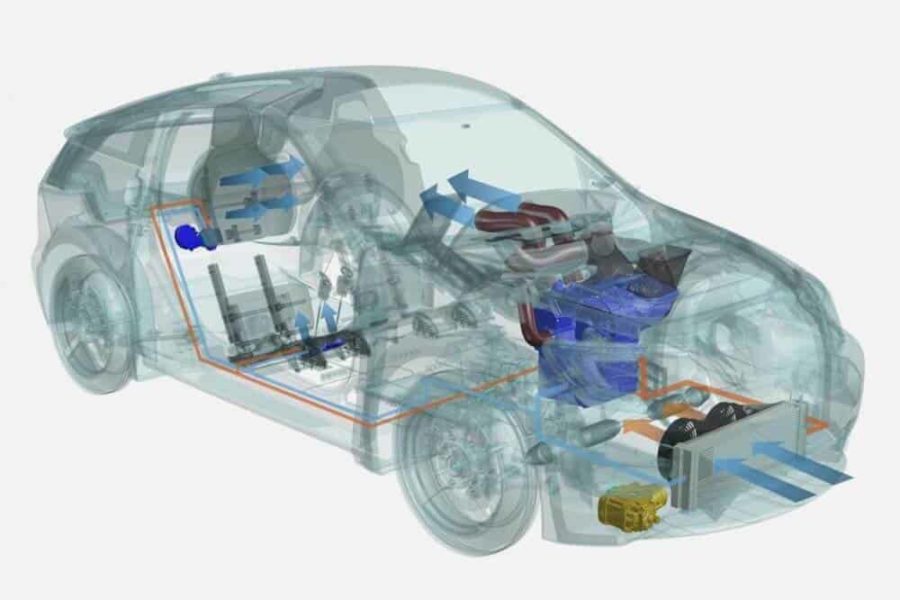

The Visio.M achieves maximum efficiency not only through temperature control of the passenger space, but also by integrating the performance electronics into a holistic thermal management system. This allows to use the waste heat the motor and the performance electronics to heat the passenger compartment in the winter while excess capacity of the air conditioning system can be used to cool the performance electronics in the summer.

The thermal management system is controlled by intelligent, self-adaptive software based on an evolutionary algorithm, developed at Technische Universität München. It evaluates the various sensor signals for temperature and humidity and automatically finds the optimal settings with regard to comfort, safety and efficiency using a simplified computer model.

A further comfort improvement can be achieved using a remote control of the air conditioning system via a smart phone. Thus shortly before his arrival, the driver can start heating or cooling. A preliminary air conditioning during charging could be added as well. Thanks to the open software platform of Visio.M adding of extensions is extremely simple and can take place without workshop visit.

The intelligent coupling of all heating and cooling functions for passengers and performance electronics results in a very compact climate control unit. “Here, we demonstrate an approach that can serve as a model for combustion engine models, as well.” In a combustion engine vehicle efficient climate control would generate savings, especially with regard to air conditioning. Beyond that, the compact system requires less space, which provides additional freedom for design and safety.

Participants in the Visio.M consortium were, in addition to the automotive companies BMW AG (lead manager) and Daimler AG, the Technische Universitaet Muenchen as a scientific partner, and Autoliv BV & Co. KG, the Federal Highway Research Institute (BAST), Continental Automotive GmbH, Finepower GmbH, Hyve AG, IAV GmbH, InnoZ GmbH, Intermap Technologies GmbH, LION Smart GmbH, Amtek Tekfor Holding GmbH, Siemens AG, Texas Instruments Germany GmbH and TÜV SÜD AG as industrial partners. The project was funded under the priority program “Key Technologies for Electric Mobility – STROM” of the Federal Ministry for Education and Research (BMBF) for a term of 2.5 years with a total budget of 10.8 million euro.