According to the WHO, about 7 million people die each year due to air pollution. Particulate matter (PM) triggers inflammatory responses in the human body, causing asthma and other respiratory and cardiovascular diseases. It is more fatal for young and growing students. The Korea Institute of Civil Engineering and Building Technology (KICT) has reduced time required to remove particulate matter from the classroom by more than 30% by optimizing the locations of supply and return diffusers for air supplied into the classroom.

Reducing Particulate Matter has been a global task. In 2018, the Korean Ministry of Education (MOE) announced “Measures against High Concentration of Particulate Matter in Classrooms” designed to tighten the fine particles (PM2.5) standards for classrooms to the annual average of 15㎍/㎥. The MOE has strived to remove particulate matter from classrooms, completing its drive to install air purifiers in all elementary schools across the country last year.

As part of these efforts, a research team at KICT led by Dr. Choon-Man Jang developed a central heating, ventilation and air-conditioning system (HVAC) system equipped with HEPA filters for elementary schools in Korea.

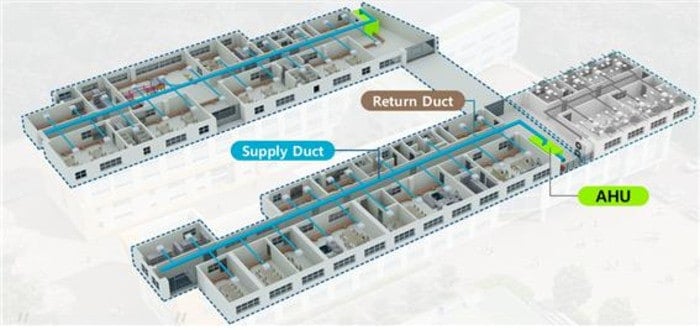

This central HVAC requires an air handling unit (AHU) to be installed for each floor of the school to supply clean air to classrooms through ducts. Supply diffusers connected to ducts supply clean air into each classroom, while the indoor air polluted by students’ indoor activities and inflows of particulate matter is discharged through return diffusers and then purified by the AHU.

Dr. Jang’s team applied three-dimensional numerical simulation to design the optimal positioning of supply and return diffusers. In order to demonstrate performance at the same scale as a real-life school facility in Korea, the research team built a “full-scale school environment performance test-bed” and performed experiments.

Tests were conducted to validate the performance of airflow locations – upper supply diffusers and lower window-side return diffusers – which were optimized through numerical simulation. Results show that the time it takes to remove particulate matter (PM2.5) from the validation requirement of 800 m3 per hour has been reduced by more than 30%. This improvement has been achieved by improving the circulation of indoor airflow inside the classroom and consequently reducing air stagnation.

The distributions of streamlines for upper and floor return diffusers show that the airflow discharged from the upper supply diffusers does not reach the floor fully but gets out through the return diffusers on the ceiling. When floor return diffusers are used, however, airflow from the upper supply diffusers reaches the floor where it is evenly distributed. This indicates that optimal airflow control through the optimization of the locations of return diffusers enables the efficient removal of particulate matter. Furthermore, it maintains the even distribution of indoor airflow.

This composite system can be installed not only in schools but can also be applied for a range of purposes, including other educational facilities and nursing facilities. One of its biggest advantages is that it can remove indoor particulate matter faster than other indoor ventilation systems.

Dr. Choon-Man Jang said, “Indoor particulate matter in schools directly affect students’ health, so it is very important to reduce the time it takes to remove particulates through airflow optimization.”