A team of researchers has developed a miniature implantable microphone that could pave the way for fully internal cochlear implants. This innovative device, created by scientists from MIT, Massachusetts Eye and Ear, Harvard Medical School, and Columbia University, performs on par with commercial external hearing aid microphones.

Cochlear implants have improved hearing for over a million people worldwide. However, current models are only partially implanted and rely on external hardware that limits users’ activities. The new microphone, called the UmboMic, addresses one of the major obstacles to creating a fully internalized cochlear implant.

How the UmboMic Works

The UmboMic is a tiny sensor made from biocompatible piezoelectric material. It measures small movements on the underside of the eardrum. Piezoelectric materials generate electric charges when compressed or stretched. To boost performance, the team also created a low-noise amplifier that enhances the signal while reducing electronic noise.

The device targets the umbo, a part of the middle ear that vibrates in a simple inward and outward motion. This makes it easier to detect movement compared to other areas of the ear.

Jeffrey Lang, co-senior author of the study, emphasizes the collaborative nature of the project: “It starts with the ear doctors who are with this every day of the week, trying to improve people’s hearing, recognizing a need, and bringing that need to us. If it weren’t for this team collaboration, we wouldn’t be where we are today.”

Overcoming Design Challenges

Creating the UmboMic presented several challenges. The umbo only moves by a few nanometers, requiring extremely sensitive measurement. The device also needed to be biocompatible and withstand the body’s internal environment.

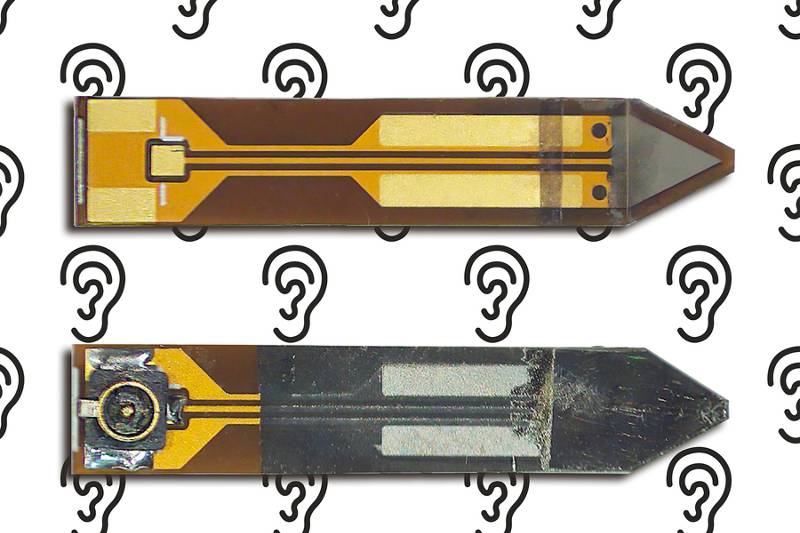

The team solved these problems by using a “sandwich” design. They created a triangular, 3mm x 3mm sensor with two layers of polyvinylidene difluoride (PVDF) on either side of a flexible printed circuit board. This microphone is about the size of a grain of rice and 200 micrometers thick – twice the width of a human hair.

Emma Wawrzynek, a co-lead author, explains their goal: “Our goal is that a surgeon implants this device at the same time as the cochlear implant and internalized processor, which means optimizing the surgery while working around the internal structures of the ear without disrupting any of the processes that go on in there.”

The researchers faced additional hurdles in fabrication and signal amplification. PVDF loses its properties at high temperatures, complicating the manufacturing process. The team developed special techniques to work around this issue.

Tests on human ear bones from cadavers showed that the UmboMic performed well within the range of human speech. The device could also distinguish very quiet sounds from background noise.

The team is now preparing for live animal studies and exploring ways to safely encapsulate the sensor for long-term use. While challenges remain, this breakthrough brings us closer to fully internal cochlear implants that could offer users greater freedom and potentially encourage more people to benefit from this technology.