Summary: Korean scientists have developed a new printhead for bioprinting that operates at 60 times the speed of conventional methods while generating significantly less heat. This advancement could dramatically accelerate the development of artificial organs and tissues for transplantation and drug testing.

Published in Sensors and Actuators B: Chemical, October 15, 2024. DOI: 10.1016/j.snb.2024.136194 | Reading time: 6 minutes

Scientists at the Korea Institute of Science and Technology (KIST) have engineered a high-performance printhead that could transform the field of bioprinting, making the creation of artificial organs and tissues faster and more precise than ever before.

The new technology achieves printing speeds of 1.2 meters per second – approximately 60 times faster than traditional methods – while maintaining temperatures below 3.2 degrees Celsius during operation, a crucial factor for preserving sensitive biological materials.

Engineering a Better Bioprinter

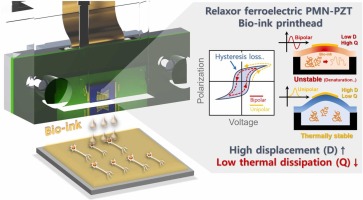

The research team, led by Dr. Byung Chul Lee at KIST’s Bionics Research Center, developed their printhead using a specialized material called PMN-PZT. This innovative design allows for simultaneous control of 16 ink ejection units, spaced just 300 μm apart, creating structures with unprecedented precision.

In testing, the team successfully printed hydrogels with a diameter of 32μm – half the size achievable with conventional methods. This level of precision, combined with the dramatic reduction in heat generation by 73.4%, opens new possibilities for creating delicate biological structures.

From Laboratory to Life-Saving Applications

The implications of this advancement extend beyond technical specifications. Current bioprinting methods, which typically use single-needle systems, make the production of complex organs like hearts, lungs, and brains a time-consuming process.

As Dr. Lee explains: “The new print head using PMN-PZT thin film material has enhanced the potential for high-resolution 3D organoid model production. We plan to commercialize a 3D bioprinter capable of creating organs applicable for transplantation and toxicity evaluation by experimenting with various bio-inks such as gelatin.”

Beyond Medicine

While medical applications drive this innovation, the technology’s ability to maintain operating temperatures below 30 degrees Celsius makes it valuable for other industries. The system could find applications in electronic component manufacturing and other fields requiring precise, temperature-sensitive printing processes.

Glossary of Terms

- Bioprinting: A 3D printing technique that uses living cells and other biological materials to create tissue-like structures

- PMN-PZT: A piezoelectric material (lead magnesium niobate-lead zirconate titanate) that can convert electrical energy into mechanical movement with high efficiency

- Hydrogels: Soft, gel-like materials used in bioprinting that can contain living cells and provide structural support

- Organoids: Miniature, simplified versions of organs grown in a laboratory

- Piezoelectric: A material property where electrical charge accumulates in response to mechanical stress, or vice versa

Test Your Knowledge

- Q: How much faster is the new printing method compared to traditional approaches?

A: 60 times faster, achieving speeds of 1.2 meters per second - Q: What is the maximum temperature increase during printing with the new system?

A: 3.2 degrees Celsius - Q: How many ink ejection units can be controlled simultaneously in the new printhead?

A: 16 units - Q: By what percentage did the new system reduce heat generation?

A: 73.4%

Enjoy this story? Get our newsletter! https://scienceblog.substack.com/

For more information about KIST and their research, visit https://eng.kist.re.kr/