Researchers at North Carolina State University have come up with a technique to embed needle-like carbon nanofibers in an elastic membrane, creating a flexible “bed of nails” on the nanoscale that opens the door to development of new drug-delivery systems.

The research community is interested in finding new ways to deliver precise doses of drugs to specific targets, such as regions of the brain. One idea is to create balloons embedded with nanoscale spikes that are coated with the relevant drug. Theoretically, the deflated balloon could be inserted into the target area and then inflated, allowing the spikes on the balloon’s surface to pierce the surrounding cell walls and deliver the drug. The balloon could then be deflated and withdrawn.

But to test this concept, researchers first needed to develop an elastic material that is embedded with these aligned, nanoscale needles. That’s where the NC State research team came in.

But to test this concept, researchers first needed to develop an elastic material that is embedded with these aligned, nanoscale needles. That’s where the NC State research team came in.

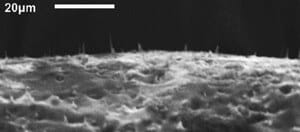

“We have now developed a way of embedding carbon nanofibers in an elastic silicone membrane and ensuring that the nanofibers are both perpendicular to the membrane’s surface and sturdy enough to impale cells,” says Dr. Anatoli Melechko, an associate professor of materials science and engineering at NC State and co-author of a paper on the work.

The researchers first “grew” the nanofibers on an aluminum bed, or substrate. They then added a drop of liquid silicone polymer. The polymer, nanofibers and substrate were then spun, so that centrifugal force spread the liquid polymer in a thin layer between the nanofibers – allowing the nanofibers to stick out above the surface. The polymer was then “cured,” turning the liquid polymer into a solid, elastic membrane. Researchers then dissolved the aluminum substrate, leaving the membrane embedded with the carbon nanofibers “needles.”

“This technique is relatively easy and inexpensive,” says Melechko, “so we are hoping this development will facilitate new research on targeted drug-delivery methods.”

The paper, “Transfer of Vertically Aligned Carbon Nanofibers to Polydimethylsiloxane (PDMS) while Maintaining their Alignment and Impalefection Functionality,” is published online in the journal ACS Applied Materials & Interfaces. Lead authors on the paper are Ryan Pearce, a Ph.D. student at NC State, and Justin Railsback, a former NC State student now pursuing a Ph.D. at Northwestern University. Co-authors are Melechko; Dr. Joseph Tracy, an assistant professor of materials science and engineering at NC State; Bryan Anderson and Mehmet Sarac, Ph.D. students at NC State; and Timothy McKnight of Oak Ridge National Laboratory.

The research was supported by the National Science Foundation and the Department of Defense, Defense Threat Reduction Agency.

“Transfer of Vertically Aligned Carbon Nanofibers to Polydimethylsiloxane (PDMS) while Maintaining their Alignment and Impalefection Functionality”

Authors: Ryan C. Pearce, Justin G. Railsback, Bryan D. Anderson, Mehmet F. Sarac, Joseph B. Tracy, Anatoli V. Melechko, North Carolina State University; Timothy E. McKnight, Oak Ridge National Laboratory

Published: online January 2013, ACS Applied Materials & Interfaces

Abstract: Vertically aligned carbon nanofibers (VACNFs) are synthesized on Al 3003 alloy substrates by direct current plasma-enhanced chemical vapor deposition. Chemically synthesized Ni nanoparticles were used as the catalyst for growth. The Si-containing coating (SiNx) typically created when VACNFs are grown on silicon was produced by adding Si microparticles prior to growth. The fiber arrays were transferred to PDMS by spin coating a layer on the grown substrates, curing the PDMS, and etching away the Al in KOH. The fiber arrays contain many fibers over 15 µm (long enough to protrude from the PDMS film and penetrate cell membranes) and SiNx coatings as observed by SEM, EDX, and fluorescence microscopy. The free standing array in PDMS was loaded with pVENUS-C1 plasmid and human brain microcapillary endothelial (HBMEC) cells and was successfully impalefected.