Although the Mars shelter competition took place entirely on Earth, the team’s final product could feasibly be built in space. The knowledge gained, however, will be used to create sustainable, low-cost housing options here, by simplifying and speeding up construction processes and saving on materials, Duarte said. He and his colleagues are already developing the technology to deploy structures in remote areas of Alaska, where temperature extremes rival those on Mars.

Coordinated by Ali Memari, Bernard and Henrietta Hankin Chair in Residential Building Construction, and with help from Ming Xiao, a professor of civil engineering, and Nathan Brown, a professor in architectural engineering, the team is designing an Alaska-ready 3D-printed model that includes a foundation, walls and a roof.

“The model is essentially a room, and you can combine rooms to build unique houses with a variety of configurations,” said Duarte. “By doing this, you can build a large house with a small printer, one room at time. You can print the entire thing on site.”

Printing with clay

Assistant Professor of Art Tom Lauerman is using 3D printing to build structures of another sort. Although much smaller in scale than a house, they are equally intriguing. And the material he is using — clay — can be found in his own backyard.

“As a sculptor, the medium I’ve worked with for many years is ceramics, but I’ve always been really interested in technology as well,” said Lauerman. “So, I began learning 3D-modeling programs, like what an architect or industrial designer would use to design things. That was partly because it was an effective way for me to draw out ideas. I would make these 3D models basically as a blueprint for something that I would then go and try to make by hand.”

As 3D printing advanced, Lauerman began to use the technology to make plastic molds, and from them to cast ceramic objects. “That worked really well,” he said, “but it was time-consuming and cumbersome.”

It was when Lauerman sought out Simpson for technical advice that the idea of 3D printing directly with clay was born. Because there were no off-the-shelf printers that suited his purpose, Lauerman, at Simpson’s suggestion, went to the College of Engineering’s Learning Factory to work with a team of students to build one.

The Bernard M. Gordon Learning Factory is a hands-on facility for engineering students to use in conjunction with capstone design and other courses. For the past five years, Lauerman has worked with these students to design and build custom 3D clay printers.

“The objects we were able to create at first were really crude; they were teeny, tiny little things,” he said. Today, however, Lauerman’s creations are much more sophisticated, and he is planning to display them in a formal exhibition in the coming year.

“3D printing allows me to experiment with nearly unlimited possibilities,” he said. “I can make things with really intricate repeating patterns that would be very difficult to do by hand, and if I want to make a tiny tweak, I can do that without having to go through the immense effort of rebuilding from scratch.”

Printing with metal

While biological materials, cement and clay are opening doors to exciting possibilities through 3D printing, Simpson said, “what’s really supercharged additive manufacturing in the last 10 years is metals.” The technology has developed to the point of allowing metal parts to be made with complex curves or cavities very difficult to achieve with subtractive processes, he explained. The results have already started to impact the manufacture of automobiles and airplanes, among other industries.

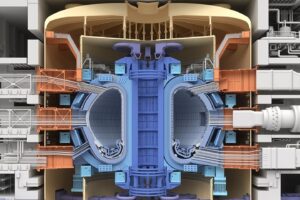

Simpson’s colleague Edward “Ted” Reutzel is one of more than a dozen researchers in the Applied Research Laboratory at Penn State who are advancing metal 3D printing. Reutzel directs the Center for Innovative Materials Processing Through Direct Digital Deposition (CIMP-3D), an 8,000 square-foot facility located at Innovation Park whose cutting-edge capabilities and expertise allow it to serve as the Additive Manufacturing Demonstration Facility for the U.S. Defense Advanced Research Project Agency (DARPA). In the past 10 years, CIMP-3D has hosted more than 6,000 visitors, spun out three start-up companies, created more than 30 new jobs in the region, and supported the launch of the world’s first additive manufacturing and design graduate program, which now enrolls over 200 industry practitioners from more than 80 different companies.

Working with the U.S. Navy in 2016, Reutzel led a team that supported the U.S. Naval Air Systems Command in designing and building the world’s first 3D-printed flight-critical component — a titanium link that helps to secure the engine to the frame of a Navy tiltrotor aircraft. Today, Reutzel and his colleagues at CIMP-3D are focused on additive manufacturing technology from early-stage research to applications for industrial use, and on helping to develop methods to efficiently assess and improve additive manufacturing part quality.

“Additive manufacturing has the potential to revolutionize manufacturing by providing on-demand production, decreasing material and manufacturing costs, allowing highly flexible designs for production, and producing features and material combinations that are not currently feasible,” said Reutzel. But obstacles remain, he said — for one, the “lack of established quality control practices for built parts poses a challenge to wider adoption.”

As Reutzel explained, the 3D printing process that enables rapid fabrication of complex parts is itself quite complex, and small process perturbations can be correlated to material defects such as voids or porosity — essentially holes in the material that are smaller than a human hair. These defects can lead to cracking and instability, jeopardizing durability and safety.

Reutzel and colleagues including Parisa Shokouhi, associate professor of engineering science and mechanics, are investigating various processes for identifying such defects, including nonlinear resonance ultrasonic spectroscopy, which can predict how long an object will last before failing, and X-ray computed tomography, which enables visualization of interior flaws within solid objects.

Allison Beese, associate professor of materials science and engineering and mechanical engineering, is also working toward quality control in metals. Beese, who directs Penn State’s Additive Manufacturing & Design Graduate Program, focuses much of her research on functionally graded materials, which combine materials with different attributes to achieve desired properties.

Beese also examines the relationships between temperature, microstructure, and mechanical properties related to the printing process. When additively manufacturing metals, for example, the raw material fed into the printer is often in the form of a metallic powder or wire feedstock. These materials are melted with a laser or electron beam, and as each layer of the desired object is added, it cools and solidifies and fuses to the layer below. This process introduces rapid heating and cooling cycles, resulting in microstructures within the material that differ drastically from those seen in cast or wrought counterparts. “To reliably use metals in structural applications, their mechanical properties must be understood and be predictable,” said Beese. “My lab’s work may ultimately aid in defining metrics for quality control and repeatability, and lead to the development of new materials.”

While safety and quality are top priorities as more and more consumer and industrial products are manufactured this way, 3D printing with multiple materials is another promising area for future research. “If we want to print a house, currently we print the concrete, but leave spaces for the windows,” Simpson explained. “Could we just switch to a transparent polymer during the process of putting in the concrete to get a window?”

The digital nature of additive manufacturing means that 5G, the next generation of wireless network technology, will create new opportunities for remote monitoring and operation, Simpson says. “Our hope is to build a 5G testbed on campus that will serve as a platform to develop, deploy, and test new protocols for additive manufacturing and other digital manufacturing technologies.” With 5G in place, he said, “We can open up entirely new avenues for quality assurance and quality control.”

From the custom watches that are already available to the artificial organs being tested for the future, 3D printing and additive manufacturing is allowing us to produce traditional products more affordably and sustainably and to create entirely new products that may transform the way we travel, build homes, and manage our health. At Penn State, researchers are using the technology in novel and exciting ways that are already impacting the world.

“Our faculty and students are working directly with industry to help solve real-world problems,” said Simpson. “It’s very exciting to be at the leading edge of the additive revolution at Penn State, and our ability to collaborate so easily strengthens our impact far beyond what any of us could do alone.”