Solar energy appears to be the only form of renewable that can be exploited at levels that match the world’s growing needs.

However, it is equally necessary to find efficient ways to store solar energy in order to ensure a consistent energy supply when sunlight is scarce. One of the most efficient ways to achieve this is to use solar energy to split water into hydrogen and oxygen, and get the energy back by consuming hydrogen in a fuel cell. But collecting solar energy on a large and sustainable scale means that such cells must be made from materials that are cheap, abundant, and have 10% solar‐to‐hydrogen conversion efficiency. Publishing in Nature Communications, an EPFL-led team of scientists has found a method to create a high-efficiency, scalable solar water splitting device using cheap materials.

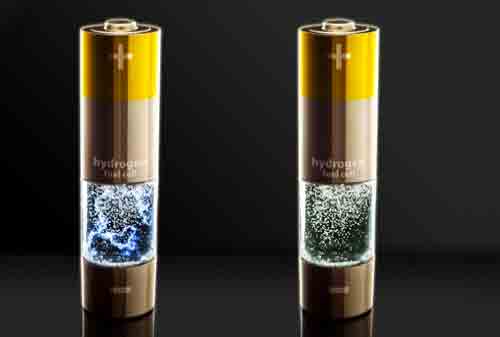

Although one of the best means of sourcing renewable energy, solar systems cannot consistently produce adequate energy since sunlight varies from time to time and place to place. A solution to this problem is a device that can store energy in the form of hydrogen for later use, offering a consistent output over time with very little pollution.

One of the most sustainable methods of producing hydrogen is photoelectrochemical (PEC) water-splitting. Solar energy is used to break water molecules into hydrogen and oxygen through a process called “hydrogen evolution reaction”. This reaction requires a catalyst, which is a chemical agent that increases its speed. In PEC water-splitting devices, a common catalyst used to split water is platinum, which is deposited on the surface of the solar panel’s photocathode – the solar panel’s electrode that converts light into electric current.

A research team at EPFL has now found a way to make efficient solar-powered water splitting devices using abundant and cheap materials. The group of Xile Hu developed a molybdenum-sulfide catalyst for the hydrogen evolution reaction, and the group of Michael Grätzel developed copper(I) oxide as a photocathode. The researchers found that the molybdenum sulfide can be deposited on the copper(I) oxide photocathode for use in PEC water splitting through a simple deposition process that can be easily expanded onto a large scale.

The technique shows comparable efficiency to other hydrogen evolution reaction catalysts like platinum, it preserves the optical transparency for the light-harvesting surface and it shows improved stability under acidic conditions, which could translate into lower maintenance. But more importantly, both the catalyst and the photocathode are made with cheap, earth-abundant materials that could greatly reduce the cost of PEC water-splitting devices in the future. According to senior author Xile Hu, the work represents a state-of-the-art example for solar hydrogen production devices.

Adapted from a news release issued by EPFL