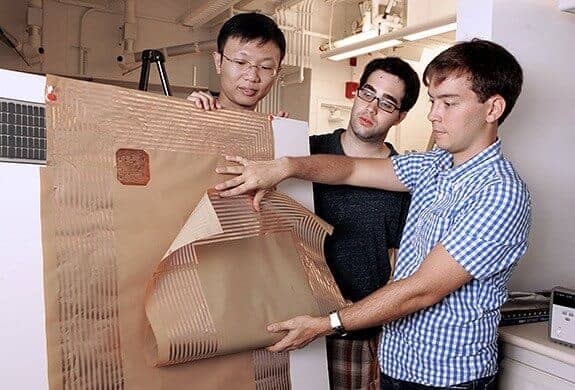

Using a modern twist on a technology developed in the 1920s, researchers at Princeton University have embedded ultrathin radios directly on plastic sheets, which can be applied to walls and other structures. The innovation could serve as the basis for new devices ranging from an invisible communications system inside buildings to sophisticated structural monitors for bridges and roads.

“We originally built this for energy management in a smart building,” said Naveen Verma, an assistant professor of electrical engineering and one of the project’s principal researchers. “Temperature sensors and occupancy sensors communicate with a central management system using distributed radio arrays that are patterned on wallpaper.”

The plastic sheets are as thin as wallpaper and can be painted without diminishing their function. They are also flexible and can be applied to irregular surfaces such as bridge decks or supporting columns. And they can be self-powered; solar cells on the plastic sheets supply electricity to the radios.

Patterning circuits on plastic, a relatively new idea, is challenging because plastic tends to melt or deform at the high temperatures used to create circuitry. In recent years, researchers have developed techniques to avoid damaging the plastic. But these methods required some alterations that lower the performance of electronic components, such as transistors, that are critical to the operation of complex devices likes radio transmitters.

“Radios have been a real challenge,” Verma said.

Radios require a relatively high frequency to operate, and that has been impractical for plastic-based electronics. Take, for example, the transistors developed by two collaborators on this project: Sigurd Wagner, a professor of electrical engineering and an expert on the use of flexible materials in electronics; and James Sturm, the Stephen R. Forrest Professor in Electrical Engineering and director of the Princeton Institute for the Science and Technology of Materials.

In a 2008 research paper, “Highly Stable Amorphous-silicon Thin-film Transistors on Clear Plastic,” the pair described developing a method for printing circuits without melting the underlying plastic. Sturm and Wagner developed a method and a new kind of circuit material that reduced that temperature from about 1,000 degrees Celsius to 300 degrees.

At that temperature, plastic worked well. But to create the working circuitry, Sturm and Wagner had to alter some of the properties of the components. And that spelled trouble for would-be radio designers.

The central difficulty lay in the new type of transistors developed for the plastic application. Transistors, often called the building block of modern electronics, are devices that control or switch the flow of electrons in circuits. They are cheap and incredibly efficient; computer manufacturers pack billions on microchips the size of a thumbnail. But their function rests on the speedy movement of electrons through a silicon crystal that forms the base of the transistor.

To make their low-temperature circuits, Sturm and Wagner used amorphous silicon in transistors rather than crystalline silicon. The amorphous silicon does not require the high temperature of the crystal form, but it also lacks the crystal’s highly ordered inner structure. For electrons, that switch is like changing from a smooth superhighway to a bumpy gravel road.

“These transistors do not perform nearly as well as the ones that Intel would make on one of its chips,” Sturm said. “In fact, if you tried to make the radio with a circuit that Intel would use, but with our transistors on plastic, it simply would not work.”

It was a puzzling challenge. Super-efficient transistors are so fundamental to modern circuitry that working around them seemed anachronistic, like putting a crank starter on a new sports car.

“You could say we are taking a page out of history,” Sturm said. “The genesis of the idea is, how do you make something when you cannot rely on high-performance transistors?”

In a modern radio, the frequency depends on the movement of electrons across a transistor: the faster the movement, the higher the frequency. The challenge for the researchers was to find a way to speed up the electrons despite the low-performing amorphous silicon transistors.

One way was to revisit ideas used before the development of the transistor revolutionized electronics. Before then, electronics depended on vacuum tubes, which were slower and less responsive than transistors.

“Many of these circuits went out years ago with vacuum tube technology,” Wagner said. “But I call Naveen the Mozart of circuits. He just knows all of them, and the ways they function, and the ways that we might be able to take advantage of them.”

Verma and electrical engineering graduate students Liechao Huang, Warren Rieutort-Louis, Yingzhe Hu and Josue Sanz Robinson hit upon the idea of using a circuit developed in 1922 by the father of FM radio, Edwin Armstrong. Called a super-regenerative circuit, the setup could use other components to increase the radio’s frequency and bypass the relative poor performance of the amorphous silicon transistors.

The super-regenerative circuit bounces electrons between a capacitor and an inductor, causing energy to be stored and discharged from each. The energy changes caused by the rapid bouncing create the radio’s frequency. And because the speed of the bouncing depends on the super-regenerative circuit’s capacitor and inductor — and not the transistors — it can allow the radio to operate at a relatively high frequency even if the transistors are poor quality.

“Essentially, you take the electrons and you slosh them back and forth between the inductor and capacitor, and the rate of this sloshing does not depend on getting electrons through the transistor — that means we can operate at frequencies that in some way are not limited by the transistors,” Verma said. “But the key is to not lose very many electrons during this sloshing, because every electron you lose needs to be compensated through those transistors. So you need very high-quality capacitors and inductors.”

This proved to be an advantage for the researchers. Building large inductors is generally easier than building small ones. And because the radios were designed to fit onto a typical wall, the researchers had plenty of space. In the end, the circuit worked perfectly with the new system. Despite the poor-quality transistors, the radio functioned well at the large scale.

“No one looks to ‘big’ as a place where you can get improvement in performance,” Verma said. “That is where our breakthrough came — when you go bigger, what do you have at your disposal to make things work better?”

As a next step, the research team is working with Branko Glišic, an assistant professor of civil and environmental engineering, to develop a flexible structural health monitoring system for use on bridges, buildings, pipelines and other structures. Currently, engineers can use single-point sensors or fiber optic strips to detect structural problems, but the devices can collect data over relatively small spaces.

“The problem is that many failures develop over large areas and you cannot detect that at an early stage,” said Glišic, who is working to develop the sensors with a Federal Highway Administration grant.

The 2007 collapse of a highway bridge in Minneapolis, for example, developed over a gusset plate with an area of several square meters, far too large for current monitoring systems to practically survey.

“In this large area of structure, which is really huge, the problem can start at virtually any point and if you don’t have sensors at that point, you are not likely to find the problem before the damage becomes substantial,” he said.

Unlike the point systems, the plastic sensing sheets would contain many linked sensors and be able to detect impending problems over a wide area. The technology is not ready for deployment — the researchers are currently conducting tests on scale models — but results have been encouraging.

“We will have a prototype in September, but it will probably need several more years of research and development,” Glišic said. “We are moving ahead, step by step.”

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!