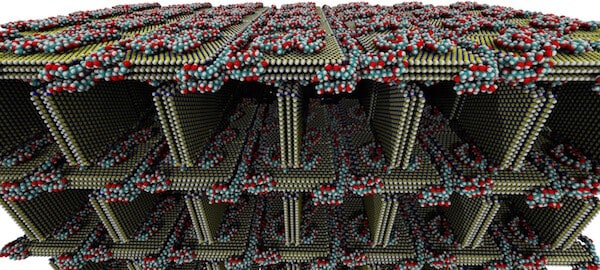

Rice University materials scientists have created a light foam from two-dimensional sheets of hexagonal-boron nitride (h-BN) that absorbs carbon dioxide.

They discovered freeze-drying h-BN turned it into a macro-scale foam that disintegrates in liquids. But adding a bit of polyvinyl alcohol (PVA) into the mix transformed it into a far more robust and useful material.

The foam is highly porous and its properties can be tuned for use in air filters and as gas absorption materials, according to researchers in the Rice lab of materials scientist Pulickel Ajayan.

Their work appears in the American Chemical Society journal ACS Nano.

The polyvinyl alcohol serves as a glue. Mixed into a solution with flakes of h-BN, it binds the junctions as the microscopic sheets arrange themselves into a lattice when freeze-dried. The one-step process is scalable, the researchers said.

“Even a very small amount of PVA works,” said co-author and Rice postdoctoral researcher Chandra Sekhar Tiwary. “It helps make the foam stiff by gluing the interconnects between the h-BN sheets – and at the same time, it hardly changes the surface area at all.”

In molecular dynamics simulations, the foam adsorbed 340 percent of its own weight in carbon dioxide. The greenhouse gas can be evaporated out of the material, which can be reused repeatedly, Tiwary said. Compression tests showed the foam got stiffer through 2,000 cycles as well.

And when coated with PDMS, another polymer, the foam becomes an effective shield from lasers that could be used in biomedical, electronics and other applications, he said.

Ultimately, the researchers want to gain control over the size of the material’s pores for specific applications, like separating oil from water. Simulations carried out by co-author Cristiano Woellner, a joint postdoctoral researcher at Rice and the State University of Campinas, Brazil, could serve as a guide for experimentalists.

“It’s important to join experiments and theoretical calculations to see the mechanical response of this composite,” Woellner said. “This way, experimentalists will see in advance how they can improve the system.”

Rice graduate student Peter Owuor is lead author of the paper. Co-authors are Ok-Kyung Park, a visiting scholar at Rice and a postdoctoral researcher at Chonbuk National University, Republic of Korea; Rice postdoctoral researchers Almaz Jalilov and Rodrigo Villegas Salvatierra and graduate students Luong Xuan Duy, Sandhya Susarla and Jarin Joyner; Rice alumnus Sehmus Ozden, now a postdoctoral fellow at Los Alamos National Laboratory; Robert Vajtai, a senior faculty fellow at Rice; Jun Lou, a Rice professor of materials science and nanoengineering; and James Tour, Rice’s T.T. and W.F. Chao Chair in Chemistry as well as a professor of computer science and of materials science and nanoengineering; and Professor Douglas Galvão of the State University of Campinas. Ajayan is chair of Rice’s Department of Materials Science and NanoEngineering, the Benjamin M. and Mary Greenwood Anderson Professor in Engineering and a professor of chemistry.

The Air Force Office of Scientific Research and its Multidisciplinary University Research Initiative funded the research.

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!