Researchers from the University of Toronto have created a new way to recycle steel that could help reduce carbon emissions in various manufacturing industries and lead to a circular steel economy.

The method, described in a paper published in Resources, Conservation & Recycling, introduces an innovative oxysulfide electrolyte for electrorefining, which removes copper and carbon impurities from molten steel while also producing liquid iron and sulfur as by-products.

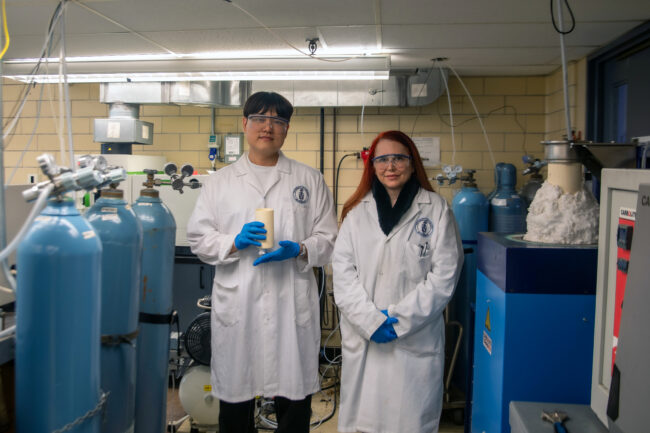

“Our study is the first reported instance of electrochemically removing copper from steel and reducing impurities to below alloy level,” says Gisele Azimi, the Canada Research Chair in Urban Mining Innovations and co-author of the paper.

Currently, only 25% of steel is produced from recycled material. However, the global demand for greener steel is expected to increase over the next 20 years as governments worldwide strive to reach net-zero emission goals. Steel production is one of the highest contributors to carbon emissions in the manufacturing sector, generating nearly two tonnes of carbon dioxide per tonne of steel produced.

Overcoming Limitations in Traditional Steel Recycling

Traditional steel recycling methods use an electric arc furnace to melt down scrap metal. However, it is difficult to separate copper material from scrap before melting, resulting in its presence in recycled steel products. When the copper concentration exceeds 0.1 weight percentage (wt%) in the final steel product, it can negatively affect the properties of steel.

“The main problem with secondary steel production is that the scrap being recycled may be contaminated with other elements, including copper,” explains Azimi. Copper cannot be removed from molten steel scrap using the traditional electric arc furnace steelmaking practice, limiting the secondary steel market to producing lower-quality steel products, such as reinforcing bars used in the construction industry.

Expanding the Secondary Steel Market with Electrorefining

The team designed an electrochemical cell that can withstand temperatures up to 1600 degrees Celsius. Inside the cell, electricity flows between the negative electrode (cathode) and the positive electrode (anode) through a novel oxysulfide electrolyte made from slag, a waste derived from steelmaking that often ends up in cement or landfills.

“We put our contaminated iron that has the copper impurity as the anode of the electrochemical cell,” says Azimi. “We then apply an electromotive force, which is the voltage, with a power supply and we force the copper to react with the electrolyte.”

Co-author Jaesuk (Jay) Paeng adds, “The electrolyte targets the removal of copper from the iron when we apply electricity to the cell. When we apply electricity on the one side of the cell, we force the copper to react with the electrolyte and come out from iron. At the other end of the cell, we simultaneously produce new iron.”

The team collaborated with Tenova Goodfellow Inc., a global supplier of advanced technologies, products, and services for metal and mining industries. Looking ahead, they aim to enable the electro-refining process to remove other contaminants from steel, such as tin.

“Our method has great potential to offer the steelmaking industry a practical and easily implementable way to recycle steel to produce more of the demand for high-grade steel globally,” says Azimi.

Headline: University of Toronto Researchers Develop Innovative Steel Recycling Method to Reduce Carbon Emissions and Promote Circular Economy

Here are some additional resources for readers who want to learn more:

- Life Cycle Assessment of Steel Production https://www.steel.org/sustainability/life-cycle/

- How Recycled Steel is Made https://www.isri.org/docs/default-source/commodities/isri_commodities_factsheets_iron_steel_sm.pdf?sfvrsn=aee5a313_18

- The Need for Sustainable Steel Production https://worldsteel.org/steel-topics/sustainability/sustainability-indicators-2023-report/

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!