UC Riverside Researchers Develop Low-Cost, Reliable Alternative to Electronic Monitors

An invention from the University of California, Riverside could transform the way we prevent blood clots and strokes in patients. Researchers have created an air-powered computer that monitors medical devices without relying on electronic sensors, potentially lowering healthcare costs and improving reliability.

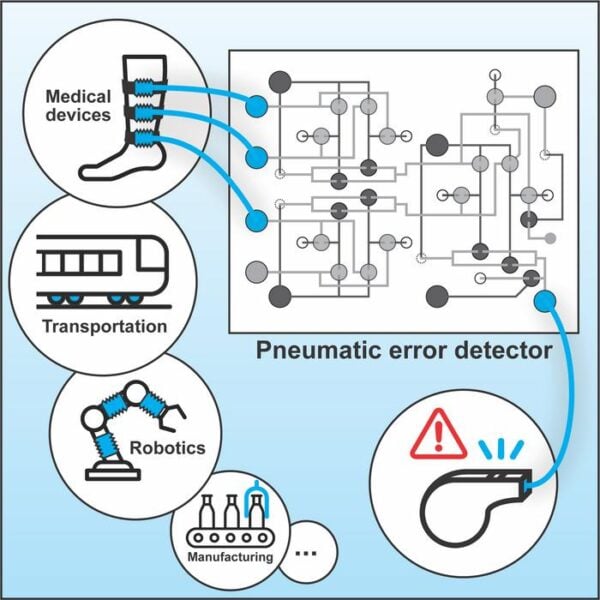

The study, published in the journal Device, describes a pneumatic computer that uses air pressure to detect failures in intermittent pneumatic compression (IPC) devices. These life-saving machines prevent blood clots by periodically inflating leg sleeves to increase blood flow.

“IPC devices can save lives, but all the electronics in them make them expensive. So, we wanted to develop a pneumatic device that gets rid of some of the electronics, to make these devices cheaper and safer,” explains William Grover, associate professor of bioengineering at UC Riverside and the study’s corresponding author.

How It Works: Air-Powered Logic

The air-powered computer operates on principles similar to electronic circuits, using parity bit calculations to detect errors. The device uses differences in air pressure flowing through 21 tiny valves to count binary digits (ones and zeros). If an error is detected, the computer immediately blows a whistle, alerting healthcare providers to potential issues with the IPC device.

This innovative approach offers several advantages over traditional electronic monitoring systems:

1. Lower cost: By eliminating expensive electronic components, the air-powered computer could significantly reduce the overall cost of IPC devices.

2. Increased reliability: The pneumatic system is less susceptible to electronic failures and can operate in environments that are challenging for electronics, such as high humidity or high temperature settings.

3. Immediate feedback: The whistle alarm provides instant notification of device malfunction, potentially improving patient safety.

Grover demonstrates the effectiveness of the system in a video, showing how the air-powered computer detects damage to an IPC device within seconds of it occurring.

Why it matters: This invention could have far-reaching implications for medical device design and patient care. By making IPC devices more affordable and reliable, the air-powered computer could increase access to this life-saving technology, particularly in resource-limited settings or challenging environments where electronic devices may be impractical.

The potential applications of air-powered computing extend beyond medical devices. Grover envisions using this technology to create safer robots for hazardous environments, such as grain silos where explosive conditions make electronic devices dangerous.

“Once a new technology becomes dominant, we lose awareness of other solutions to problems,” Grover reflects. “One thing I like about this research is that it can show the world that there are situations today when 100-plus-year-old ideas can still be useful.”

This research serves as a reminder that innovation doesn’t always mean developing entirely new technologies. Sometimes, revisiting and adapting older concepts can lead to breakthroughs that address modern challenges in unexpected ways.

As healthcare providers and engineers continue to seek more cost-effective and reliable solutions for patient care, air-powered computing could play a crucial role in the next generation of medical devices. By combining the simplicity of pneumatics with the logic of modern computing, this technology offers a promising path forward in the ongoing effort to improve healthcare outcomes while reducing costs.

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!