Researchers at Iowa State University are exploring the use of 3D printing technology to manufacture tungsten parts for nuclear reactors, potentially revolutionizing the production of components for extreme environments.

Summary: A team led by Dr. Sougata Roy has received a $1 million grant to study 3D printing of tungsten-based alloys for use in nuclear reactors, aiming to overcome traditional manufacturing challenges.

Estimated reading time: 5 minutes

In the quest for clean energy solutions, nuclear power plays a significant role. Now, researchers are turning to advanced manufacturing techniques to enhance the efficiency and durability of nuclear reactor components. Dr. Sougata Roy, an assistant professor of mechanical engineering at Iowa State University, is leading a groundbreaking study on 3D printing tungsten parts for use in extreme conditions within nuclear reactors.

The U.S. Department of Energy has awarded Roy a four-year, $1 million grant to explore the possibilities of using additive manufacturing, commonly known as 3D printing, to create shields and components for nuclear reactors. This research could potentially transform how we approach the construction and maintenance of nuclear power facilities.

The DREAM-TEAM Project

Roy’s initiative, dubbed the DREAM-TEAM project (Developing a Robust Ecosystem for Additive Manufacturing of Tungsten for Extreme Applications and Management), brings together experts from multiple institutions. The team includes researchers from the University of North Dakota and three U.S. Department of Energy national laboratories: Ames National Laboratory, Argonne National Laboratory, and Oak Ridge National Laboratory.

“This work in advanced manufacturing, particularly in using additive manufacturing, is about making a difference,” said Roy, highlighting the project’s potential impact on clean energy production.

Why Tungsten?

Tungsten is a prime candidate for use in nuclear reactors due to its exceptional properties. It maintains strength at high temperatures, has a high melting point, resists erosion under high-energy neutron irradiation, and retains low levels of radioactive tritium. These characteristics make it ideal for the inner walls of fusion reactors.

However, tungsten’s hardness and brittleness make it challenging and expensive to work with using conventional manufacturing methods. This is where 3D printing comes into play.

The 3D Printing Process

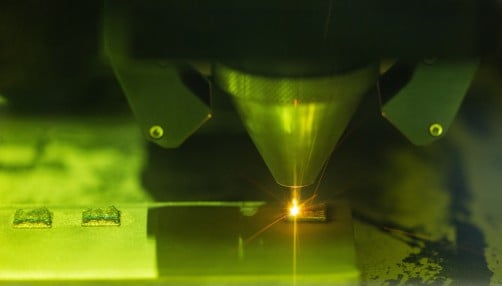

The researchers plan to use a technique called laser powder-blown directed-energy deposition to 3D print tungsten-based alloys. This process involves using a laser under oxygen-controlled conditions to process tungsten powder, building up the metal layer by layer.

Roy, who has experience in 3D printing other steel-based alloys for nuclear energy applications, emphasizes that the most unique aspect of the project isn’t the printing itself. Instead, it’s the physics-based modeling and computational simulations of the printing process that will complement the experimental work.

“We’ll start with pure tungsten,” Roy explained. “Eventually we’ll develop new alloys to resolve this cracking challenge.”

Implications and Future Applications

The success of this research could have far-reaching implications for the nuclear energy sector. By enabling the production of more durable and efficient components, it could contribute to the overall safety and effectiveness of nuclear reactors. This, in turn, could bolster nuclear energy’s position as a clean power source.

Currently, nuclear power accounts for about 19% of electricity production in the United States, according to the U.S. Energy Information Administration. Innovations in manufacturing processes for reactor components could potentially increase this percentage, contributing to a cleaner energy future.

While the focus of this study is on nuclear reactor components, the techniques and knowledge gained could potentially be applied to other industries requiring materials that can withstand extreme conditions.

As we look towards a future powered by clean energy, research like the DREAM-TEAM project reminds us of the crucial role that materials science and advanced manufacturing play in making that future a reality.

Quiz

- What is the main material being studied for 3D printing in this research? a) Steel b) Titanium c) Tungsten d) Aluminum

- What is the name of the 3D printing technique mentioned in the article? a) Fused deposition modeling b) Stereolithography c) Laser powder-blown directed-energy deposition d) Selective laser sintering

- What percentage of U.S. electricity comes from nuclear power, according to the article? a) 10% b) 19% c) 25% d) 36%

Answers:

- c) Tungsten

- c) Laser powder-blown directed-energy deposition

- b) 19%

For further reading:

- U.S. Energy Information Administration – Nuclear Power in the U.S.

- Department of Energy’s EPSCoR Program

Glossary of Terms

- Additive Manufacturing: A process of creating objects by building them up layer by layer, also known as 3D printing.

- Tungsten: A hard, rare metal with a very high melting point, used in various industrial applications.

- Nuclear Reactor: A device that initiates and controls a sustained nuclear chain reaction.

- Fusion Reactor: A device that generates energy by fusing atomic nuclei together.

- Tritium: A radioactive isotope of hydrogen.

- Directed-energy Deposition: A 3D printing process that uses focused thermal energy to fuse materials as they are deposited.

Enjoy this story? Get our newsletter! https://scienceblog.substack.com/

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!