Summary: UC Santa Cruz researchers have discovered a new chemical process that transforms waste vegetable oil into biodiesel using relatively mild temperatures. The method, which converts about 85% of used oil into biodiesel, could make this alternative fuel more accessible to farms and industrial users by simplifying production and reducing energy requirements.

Journal: Energy & Fuels, October 3, 2024, DOI: 10.1021/acs.energyfuels.4c03643 | Reading time: 4 minutes

A Cleaner Path to Diesel Fuel

In an era where diesel fuel powers much of the world’s transportation and industry, finding cleaner alternatives has never been more crucial. Now, chemists at UC Santa Cruz have developed a promising solution that could help reduce carbon emissions while putting waste oil to good use.

The research, published in Energy & Fuels, introduces a new chemical process that makes biodiesel production simpler and more energy-efficient than ever before. The breakthrough comes at a critical time – in 2022, the U.S. transportation sector alone consumed about 3 million barrels of diesel daily, contributing to approximately 10% of the nation’s energy-related CO2 emissions.

A Simple Solution

The new method centers on a chemical called sodium tetramethoxyborate (NaB(OMe)4), which offers several distinct advantages over traditional biodiesel production techniques. One of the most significant benefits is that it allows for easy separation of the biodiesel from production byproducts – they can simply be poured off.

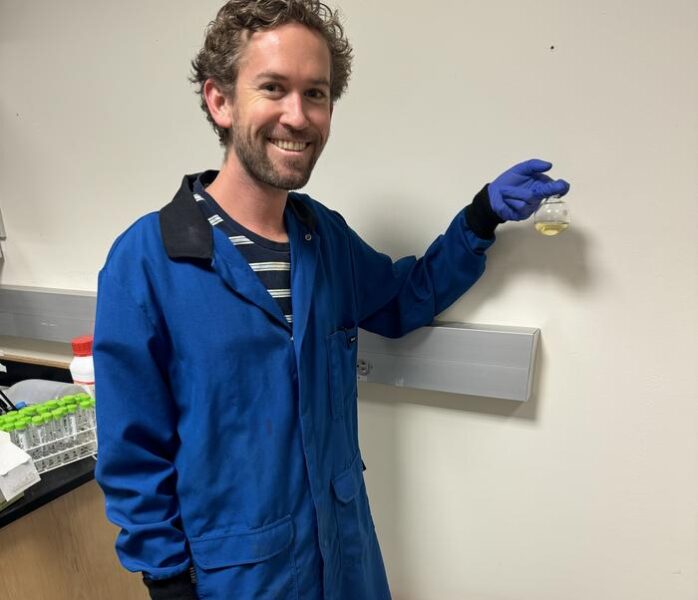

“I always wanted to work on biodiesel,” says Kevin Lofgren, a Ph.D. student in chemistry at UC Santa Cruz and the study’s lead author. “I started exploring this new material that we made to see if it could attack the fats in oil to help catalyze biodiesel, and it all flowed from there.”

Making Green Fuel Greener

The process represents a significant improvement over existing methods. Current biodiesel production often creates soap as a byproduct, making purification difficult, or relies on palm oil that contributes to deforestation. Many methods also require high temperatures and pressures.

“To make energy takes a lot of energy,” explains Scott Oliver, professor of chemistry and biochemistry. “Our method uses waste oil and mild heating, compared to current petroleum refineries that are energy consuming and pollution causing.”

The new technique operates at just 40°C (104°F) – lower than the temperature of boiling water – and converts about 85% of waste oil into biodiesel that meets nearly all industry standards for vehicle use.

From Lab to Field

The implications could be far-reaching, particularly for industrial applications. “Everybody needs energy—every farm, food production plant, and transportation vehicle depend on it,” Oliver notes. “This could really impact people. This process can be done at just above room temperature and it’s reusable. You don’t need to have a refinery; you can potentially use this method on a farm.”

Key Terms

- Biodiesel: A renewable fuel made from vegetable oils or animal fats

- Transesterification: The chemical process used to convert oils into biodiesel

- Sodium Tetramethoxyborate: The key chemical compound that enables this new biodiesel production method

- Carbon-neutral: Not adding new carbon dioxide to the atmosphere in net

Test Your Knowledge

- What temperature is required for the new biodiesel production method?

Answer: 40°C (104°F)

- What percentage of waste oil can be converted to biodiesel using this method?

Answer: 85%

- How much diesel did the U.S. transportation sector use daily in 2022?

Answer: About 3 million barrels

- What is one major advantage of the new method?

Answer: The biodiesel can be easily separated from byproducts by simply pouring them off

Enjoy this story? Get our newsletter! https://scienceblog.substack.com/

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!