A team of Empa researchers has created a remarkable new biomaterial that’s not only completely biodegradable but also tear-resistant and surprisingly versatile. The secret? It’s alive.

This innovative mycelium-based material combines strong mechanical properties with dynamic living functions, potentially transforming how we approach sustainable materials from food packaging to electronics.

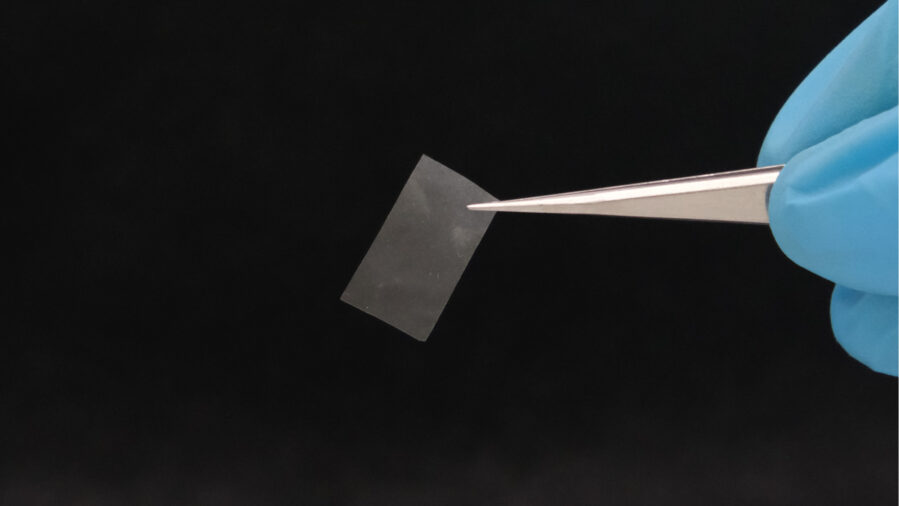

In a study published in Advanced Materials, scientists from Empa’s Cellulose and Wood Materials laboratory demonstrated how mycelium from the common split-gill mushroom can be processed into functional films and emulsions without the chemical treatments that typically compromise sustainability in biomaterials.

Nature’s Ready-Made Solution

Unlike traditional approaches to fungal materials that strip away the living components, these researchers chose to harness the complete living system. The split-gill mushroom naturally produces an extracellular matrix full of useful biomolecules as it grows.

“The fungus uses this extracellular matrix to give itself structure and other functional properties. Why shouldn’t we do the same?” explains Empa researcher Ashutosh Sinha, lead author of the study.

“Nature has already developed an optimized system,” adds Gustav Nyström, head of the Cellulose and Wood Materials lab, highlighting the elegance of the approach.

The researchers didn’t rely entirely on chance, however. They carefully selected a specific strain of the split-gill fungus that produces high levels of two valuable compounds:

- Schizophyllan – a nanofiber less than a nanometer thick but more than a thousand times as long

- Hydrophobin – a soap-like protein that gathers at interfaces between different liquids

Together, these natural biomolecules give the fungal material exceptional properties without requiring chemical modifications that would reduce biodegradability.

Self-Improving Emulsions and Strong Films

What can this living material actually do? The study demonstrated two impressive applications that showcase its versatility.

First, the researchers created emulsions stabilized by the living mycelium. Emulsions—mixtures of liquids that don’t normally combine, like oil and water—are common in foods, cosmetics, and industrial products but typically require synthetic stabilizers to prevent separation.

The living mycelium provides a continuous supply of natural emulsifiers. “This is probably the only type of emulsion that becomes more stable over time,” notes Sinha. The study showed these living emulsions exhibited 3.6 times slower phase separation compared to conventional alternatives.

Even more impressive were the thin films created from the mycelium. These transparent, plastic-like sheets achieved 2.5 times higher tensile strength after growth—substantially stronger than any pure mycelium materials previously developed.

Responsive to Its Environment

How might these materials be used in everyday life? Could living materials actually be practical in consumer products?

The researchers envision numerous possibilities. Since the fungal material is non-toxic and edible, it could serve as a natural emulsifier in food and cosmetic products. The films might replace conventional plastics in packaging applications where biodegradability is valued.

Most intriguingly, the material responds to environmental conditions like humidity, opening possibilities for smart applications. The fungal film reacts reversibly to moisture and could function as a biodegradable humidity sensor. The research team demonstrated that humidity could trigger superhydrophobic patterning, mechanical actuation, and even targeted degradation of lignocellulosic materials.

“Biodegradable materials always react to their environment,” says Nyström. “We want to find applications where this interaction is not a hindrance but maybe even an advantage.”

The Future of Fungal Engineering

Sinha envisions compostable bags that actively decompose organic waste: “Instead of compostable plastic bags, it could be used to make bags that compost the organic waste themselves.”

The team is also developing a biodegradable battery combining their living material with previous research on fungal and paper batteries. “We want to produce a compact, biodegradable battery whose electrodes consist of a living ‘fungal paper’,” explains Sinha.

As sustainable materials become increasingly crucial in addressing environmental challenges, this living mycelium platform offers a fascinating alternative to conventional approaches. By working with nature’s existing solutions rather than against them, these researchers have created a promising framework for future materials that are both high-performing and environmentally responsible.

The study represents an elegant intersection of traditional fiber processing methods with the emerging field of living materials. As Nyström puts it, they are “combining the proven methods for processing fiber-based materials with the emerging field of living materials.”

With its unique combination of biodegradability, strength, and responsiveness to environmental stimuli, this living fungal material may soon grow into applications we haven’t yet imagined.

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!