In a significant advance for robotics and materials science, researchers have developed a collective of robots that can transition between solid and liquid-like states, supporting weights hundreds of times greater than themselves before melting away on command. The innovation brings us one step closer to programmable matter that can change its physical properties at will.

The research team, led by scientists at UC Santa Barbara and Dresden University of Technology, drew inspiration from an unlikely source: developing embryos. Their findings, published in the February 21 issue of Science, demonstrate how simple robotic units can work together to create material-like behaviors previously seen only in science fiction.

“We’ve figured out a way for robots to behave more like a material,” said Matthew Devlin, lead author of the study and former doctoral researcher at UC Santa Barbara.

The system consists of disk-shaped robots, resembling small hockey pucks, that can rapidly switch between being rigid enough to support substantial loads and fluid enough to flow into new shapes. This dual capability solves a fundamental challenge in robotics: creating structures that are both strong and adaptable.

“Robotic materials should be able to take a shape and hold it,” explained Elliot Hawkes, professor of mechanical engineering at UC Santa Barbara, “but also able to selectively flow themselves into a new shape.”

Learning from Nature

The breakthrough came from studying embryonic development, where cells naturally demonstrate this ability to transition between fluid and solid states. “Living embryonic tissues are the ultimate smart materials,” said Otger Campàs, director of Physics of Life at Dresden University of Technology. “They have the ability to self-shape, self-heal and even control their material strength in space and time.”

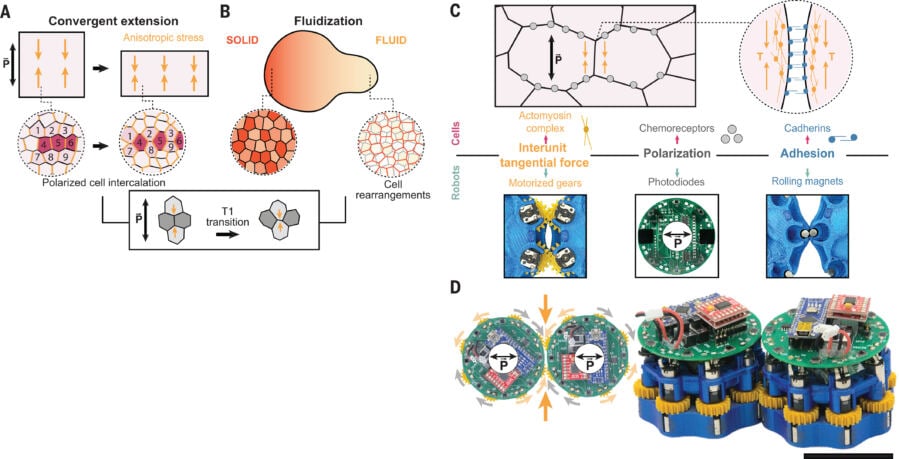

The researchers focused on three key biological processes: the forces cells use to move around each other, their coordination through biochemical signals, and their ability to stick together. They then translated these natural mechanisms into engineering solutions.

Each robot in the collective features eight motorized gears around its perimeter and magnets for adhesion to neighboring units. The gears create forces between robots similar to those between cells in living tissue, while the magnets mirror cellular adhesion. Light sensors with polarizing filters help coordinate the robots’ movements, similar to how cells respond to biochemical signals during embryonic development.

From Theory to Practice

In demonstrations, the robot collective showed remarkable capabilities. It could form complex structures like arches, repair gaps in its formation, and even function as tools by flowing around objects and then rigidifying to manipulate them. Perhaps most impressively, the system supported the weight of a human (approximately 700 newtons) – more than 500 times the weight of a single robot – before transitioning to a flowing state.

While the current prototype consists of just 20 relatively large units, computer simulations suggest the system could be scaled to include thousands of miniaturized robots. This scaling potential could lead to truly programmable materials that can dynamically change their physical properties.

The research team’s work extends beyond robotics, offering insights into physics and biology. “The combination of these robotic collectives with machine learning strategies to control them could yield remarkable capabilities in robotic materials, bringing a science fiction dream to reality,” said Sangwoo Kim, former postdoctoral fellow in the Campàs laboratory and now assistant professor at EPFL.

The study was supported by the National Science Foundation in the United States and the Deutsche Forschungsgemeinschaft (German Research Foundation) through the Cluster of Excellence Physics of Life at TU Dresden.

This research represents a significant step toward materials that can actively control their own properties, potentially revolutionizing fields from construction to medical devices. As the technology develops, we might see structures that can adapt their shape and strength on demand, opening new possibilities in architecture, engineering, and beyond.

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!