Stanford engineers have developed a new electric reactor that could significantly reduce carbon dioxide emissions from industrial processes. This innovative technology has the potential to transform how we power energy-intensive industries, paving the way for a greener future.

Tackling the Industrial Emissions Challenge

Industrial processes in the United States are responsible for about a third of the country’s carbon dioxide emissions. That’s more than the combined annual emissions from passenger vehicles, trucks, and airplanes. Reducing these emissions is crucial for mitigating climate change, but it’s no easy task.

Enter a team of researchers from Stanford Engineering. They’ve designed and demonstrated a new type of thermochemical reactor that could be a game-changer for industrial decarbonization. This electric reactor can generate the intense heat required for many industrial processes without burning fossil fuels.

Jonathan Fan, associate professor of electrical engineering at Stanford and senior author of the study, explained, “We have an electrified and scalable reactor infrastructure for thermochemical processes that features ideal heating and heat-transfer properties. Essentially, we’re pushing reactor performance to its physical limits, and we’re using green electricity to power it.”

How the New Reactor Works

Induction Heating: The Key to Efficiency

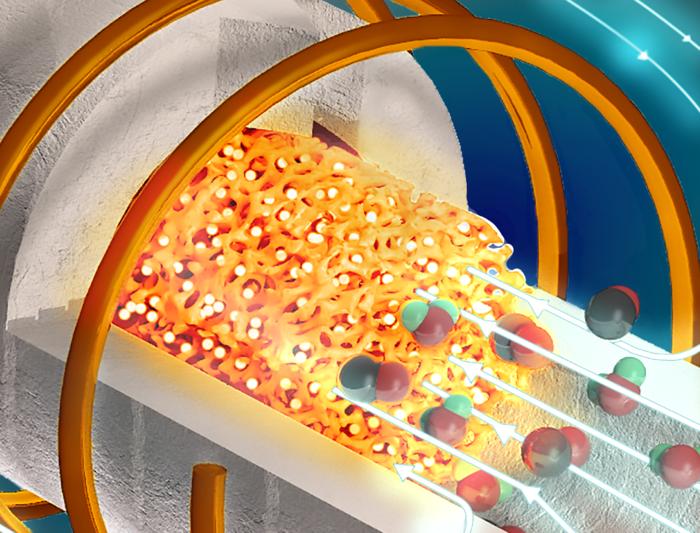

Unlike traditional thermochemical reactors that burn fossil fuels to heat a fluid, the new electrified reactor uses magnetic induction to generate heat internally. This process is similar to how induction stoves work, but on a much larger and more efficient scale.

The reactor uses high-frequency currents to inductively heat a three-dimensional lattice made of a ceramic material that poorly conducts electricity. This lattice structure is crucial, as it artificially lowers the electrical conductivity even further. The voids in the lattice can be filled with catalysts – materials that need to be heated to initiate chemical reactions.

This design offers several advantages:

- More efficient heat transfer

- Smaller reactor size compared to traditional fossil fuel reactors

- Simplified design with no need for pipes or external heat transfer

“You’re heating a large surface area structure that is right next to the catalyst, so the heat you’re generating gets to the catalyst very quickly to drive the chemical reactions,” Fan said. “Plus, it’s simplifying everything. You’re not transferring heat from somewhere else and losing some along the way, you don’t have any pipes going in and out of the reactor – you can fully insulate it. This is ideal from an energy management and cost point of view.”

Promising Results and Future Applications

The researchers tested their reactor using a chemical reaction called the reverse water gas shift reaction. This process can turn captured carbon dioxide into a valuable gas that can be used to create sustainable fuels. The results were impressive:

- Over 85% efficiency in converting electrical energy into usable heat

- Carbon dioxide converted to usable gas at the theoretically predicted rate

These outcomes suggest that the new reactor design could be highly effective in real-world applications. Fan noted, “As we make these reactors even larger or operate them at even higher temperatures, they just get more efficient. That’s the story of electrification – we’re not just trying to replace what we have, we’re creating even better performance.”

The team is already working to scale up their technology and expand its potential applications. They’re adapting the design for reactors that can capture carbon dioxide and manufacture cement. Collaborations with industrial partners in the oil and gas sectors are also underway to understand what these companies would need to adopt this technology.

Why It Matters

The development of this electric reactor could have far-reaching implications for industrial decarbonization efforts:

- Reduced carbon emissions: By replacing fossil fuel-burning processes with electric alternatives, industries could significantly cut their carbon footprint.

- Improved efficiency: The new reactor design offers better performance and energy management than traditional methods.

- Potential for sustainable fuel production: The ability to convert captured CO2 into useful gases opens up possibilities for creating more sustainable fuels.

- Adaptability: The technology could be applied to various industrial processes, from cement manufacturing to carbon capture.

As the world grapples with the urgent need to reduce greenhouse gas emissions, innovations like this electric reactor offer hope for a more sustainable industrial future. By reinventing fundamental infrastructure and breaking through existing bottlenecks, electrification could play a crucial role in decarbonizing some of the most challenging sectors of our economy.

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!