Researchers at the University of Massachusetts Amherst have developed a simple, eco-friendly coating that can turn everyday fabrics into cooling textiles. This innovation could help people stay comfortable in hot environments without relying on energy-intensive air conditioning.

How the Cooling Coating Works

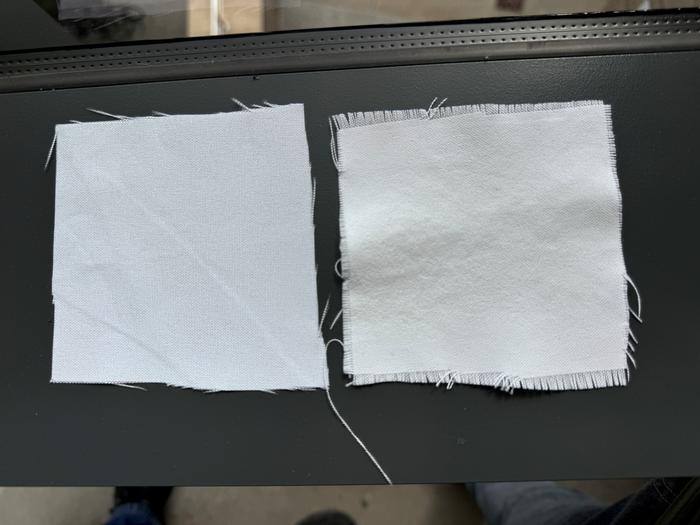

The new coating uses a combination of calcium carbonate (the main component in chalk and limestone) and barium sulfate particles to reflect harmful ultraviolet (UV) and near-infrared (near-IR) light from the sun. These particles are embedded in a thin polymer layer applied to fabric using a process called chemical vapor deposition (CVD).

Evan D. Patamia, a graduate student working on the project, explained: “If you walk out into the sunlight, you will get increasingly hot because your body and clothing are absorbing ultraviolet (UV) and near-infrared (near-IR) light from the sun. And as long as you’re alive, your body is generating heat, which can be thought of as light, too.”

By reflecting these wavelengths of light, the coated fabric prevents both solar radiation and body heat from building up underneath. Tests showed that air temperatures under the treated fabric were up to 8°F cooler than the surrounding air on a 90°F day. The difference was even more pronounced when compared to untreated fabric, with the coated material providing up to 15°F of cooling.

A More Sustainable Approach to Cooling Textiles

While other cooling fabrics exist, they often require specialized synthetic fibers or complex manufacturing processes. Some even use harmful “forever chemicals” known as PFAS in their production.

Dr. Trisha L. Andrew, the chemist and materials scientist leading the research team, highlighted the importance of finding a more sustainable solution: “Can we develop a textile coating that does the same thing using natural or environmentally benign materials?”

The team’s approach draws inspiration from an unexpected source: traditional limestone plasters used to keep houses cool in sunny climates. By adapting this age-old concept to modern textiles, they’ve created a coating that’s both effective and environmentally friendly.

The coating process is relatively simple. Fabric is first treated with a thin polymer layer using CVD. It’s then repeatedly dipped in solutions containing calcium or barium ions and solutions with carbonate or sulfate ions. This builds up layers of reflective mineral particles on the fabric surface.

Importantly, the coating appears to be durable. Megan K. Yee, another researcher on the project, simulated the effects of machine washing and found that the coating remained intact and effective.

Why It Matters:

As climate change leads to more frequent and intense heat waves, finding ways to keep people cool without increasing energy consumption is crucial. This chalk-based coating could provide a low-tech, low-cost solution for a wide range of applications:

– Outdoor workers could benefit from cooler, more comfortable uniforms.

– Sports apparel could help athletes perform better in hot conditions.

– Everyday clothing could reduce the need for air conditioning, potentially lowering energy use and costs.

– In areas without reliable electricity, treated fabrics could offer a form of “passive cooling” to help people cope with extreme heat.

Dr. Andrew is already working on scaling up the CVD process for larger fabric production, potentially bringing this technology closer to commercial reality. “What makes our technique unique is that we can do this on nearly any commercially available fabric and turn it into something that can keep people cool,” Patamia said. “Without any power input, we’re able to reduce how hot a person feels, which could be a valuable resource where people are struggling to stay cool in extremely hot environments.”

As research continues, this chalk-inspired coating could play a significant role in helping people adapt to a warming world while reducing the demand for energy-intensive cooling solutions.

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!