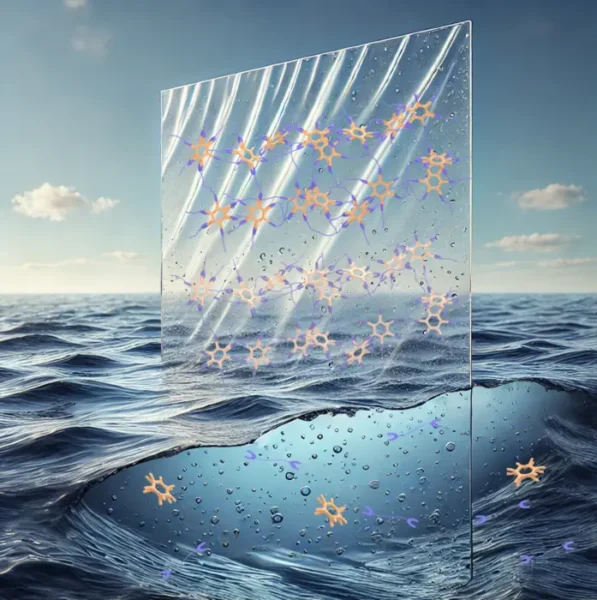

Japanese researchers have developed a novel plastic that combines the durability of conventional materials with the ability to break down completely in seawater, potentially offering a solution to ocean microplastic pollution. The material’s unique structure allows it to maintain strength on land while dissolving safely in marine environments.

Published in Science | Estimated reading time: 5 minutes

The environmental toll of plastic pollution has long seemed an intractable problem – create a material strong enough to be useful, and it persists in nature for centuries. Create one that breaks down easily, and it’s often too weak for practical use. Now, scientists at the RIKEN Center for Emergent Matter Science have thread this needle with an innovative approach.

The breakthrough lies in the material’s molecular architecture, which uses reversible cross-linked salt bridges to provide strength and flexibility. When exposed to seawater, these bridges break down in a controlled manner, allowing the plastic to dissolve without creating harmful microplastics. The base components, including a common food additive called sodium hexametaphosphate, can then be metabolized by bacteria.

“While the reversible nature of the bonds in supramolecular plastics have been thought to make them weak and unstable,” explains lead researcher Takuzo Aida, “our new materials are just the opposite.”

The manufacturing process involves an unexpected twist. When mixed in water, the components separate into two layers – one thick and viscous containing the crucial structural elements, and another watery layer containing salt ions. This “desalting” step proves critical; without it, the material becomes brittle and unusable.

The resulting plastic offers impressive versatility. By adjusting its composition, researchers can create versions ranging from hard scratch-resistant materials to flexible rubber-like substances, all with strengths comparable to or exceeding conventional plastics. The material can be reshaped at temperatures above 120°C like traditional thermoplastics and is both non-toxic and non-flammable.

Perhaps most remarkably, the plastic proves highly recyclable – 91% of the hexametaphosphate and 82% of the other primary component can be recovered after dissolution. In soil testing, sheets of the material completely degraded within 10 days, even providing nutritional benefits as fertilizer.

This development represents more than just another biodegradable plastic – it offers a new paradigm for how we might create materials that serve human needs while harmonizing with natural systems.

Glossary:

- Supramolecular Plastics

- Polymers held together by reversible interactions between molecules rather than permanent chemical bonds.

- Salt Bridges

- Chemical structures that connect different parts of the plastic, providing strength until they encounter seawater.

- Microplastics

- Plastic particles smaller than 5mm, which can accumulate in oceans and enter the food chain.

What makes this new plastic unique compared to other biodegradable plastics?

It can break down specifically in seawater while maintaining strength in normal conditions, preventing microplastic formation.

What is the critical step in manufacturing this plastic?

The “desalting” process, where components separate into two layers, with the removal of salt ions being crucial for the final material’s properties.

How long does it take for the plastic to degrade in soil?

The plastic degrades completely over the course of 10 days in soil.

What percentage of the materials can be recovered for recycling?

91% of the hexametaphosphate and 82% of the guanidinium can be recovered after dissolution.

Enjoy this story? Subscribe to our newsletter

If our reporting has informed or inspired you, please consider making a donation. Every contribution, no matter the size, empowers us to continue delivering accurate, engaging, and trustworthy science and medical news. Independent journalism requires time, effort, and resources—your support ensures we can keep uncovering the stories that matter most to you.

Join us in making knowledge accessible and impactful. Thank you for standing with us!